AC 2-Wire Inductive Sensors: Simplifying Retrofit Installations

How AC 2-Wire Inductive Sensors Simplify Retrofits

Core Working Principles of Inductive Proximity Sensors

Inductive proximity sensors work by creating an electromagnetic field that picks up on metal objects within a certain distance. Metal entering this field changes the sensor's impedance, triggering an output signal when detected. What makes these sensors so useful is their simplicity and dependability, especially when installing them into older systems. Most industrial setups find they fit right in without needing major modifications, making them a go to option wherever detecting metal parts matters. From factory floors to packaging lines, these sensors keep performing reliably day after day. Many plant managers consider them the best choice for keeping operations running smoothly without tearing apart entire control systems just to upgrade detection capabilities.

Key Advantages Over Mechanical Switches

When comparing inductive sensors to traditional mechanical switches, there are some pretty clear benefits worth noting. For starters, since they don't have any moving parts at all, inductive sensors just don't suffer from the same kind of wear and tear that breaks down mechanical components over time. That means these sensors tend to last much longer before needing replacement. Another big plus is their speed response time which makes them ideal for fast paced operations where quick detection matters. Industrial environments can get pretty rough too, with dust floating around, moisture getting everywhere, and temperatures swinging wildly throughout the day. Inductive sensors handle all this without missing a beat though, which keeps production running smoothly without constant interruptions for maintenance checks. Mechanical switches on the other hand? They usually need regular attention to keep working properly. Given all these factors, it's no surprise why so many factories and manufacturing plants across various industries are turning to inductive proximity sensors as their go to solution for reliable sensing needs.

Critical Features for Retrofit Compatibility

Compact Design for Space-Constrained Installations

AC 2 wire inductive sensors have a really big plus going for them when space matters most. The way they're built lets them squeeze right into those awkward spots inside machines or jam-packed control panels without tearing everything apart. We've seen them work great in factory automation setups where there just isn't room for bigger alternatives. Because they take up so little space on the panel, plant managers don't have to rewire entire systems just to make room. This means factories can upgrade their monitoring capabilities without breaking budgets or shutting down production lines for days while retrofitting old equipment.

Adjustable Sensing Distance Flexibility

The adjustable sensing distance in AC 2-wire inductive sensors stands out as one of their most valuable characteristics, giving them the flexibility required across different operational scenarios. Users have the ability to fine tune these sensors according to what they need, from picking up small components just inches away to monitoring larger areas where longer detection ranges matter. Because of this adaptability, many manufacturers find it possible to install these sensors in existing equipment setups without major modifications. The consistent performance remains reliable no matter what kind of detection task comes along. For industrial operations looking to upgrade their automation capabilities, this kind of versatile sensor offers real world benefits without sacrificing either function or measurement accuracy when compared to traditional alternatives.

Top AC 2-Wire Inductive Sensor Models

AC M18 Brass Capacitive with Cable Type: Space-Efficient Solution

The AC M18 brass capacitive model really shines because of how solidly built it is. Despite being tough enough to last through tough conditions, it still manages to stay small enough to fit into tricky spots. We've seen these models work wonders inside machines where there's barely room to move around, or tucked away behind crowded control panels without taking up too much space. The wiring on these units is straightforward which means installers don't get stuck dealing with complicated connections. Just plug it in and go. For factories looking to upgrade old equipment without tearing everything apart, this model saves time and headaches during installation while keeping operations running smoothly.

AC M30 87mm Plastic Model: High-Temperature Resilience

Made with heat resistant plastic, the AC M30 sensor works really well in hot environments, which is why many factories and plants choose it for their operations. When things get super hot, most sensors start acting up or break down completely, but this one holds up pretty good. That means fewer breakdowns and better results when temperature matters most. The toughness of this sensor makes all the difference in places like steel mills or chemical processing facilities where temperatures fluctuate constantly. Operators appreciate knowing they won't have to replace sensors every few weeks just because the heat got too intense.

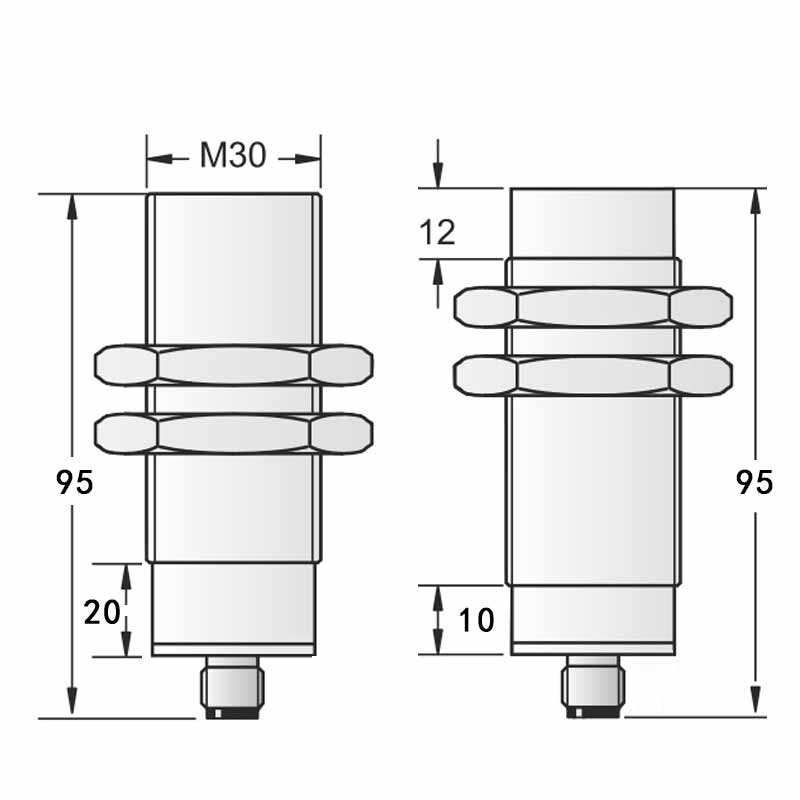

AC M30-M12 95mm Capacitive: Hybrid Connector Design

The AC M30-M12 comes with a clever hybrid connector that works really well with different types of equipment, which makes connecting everything together much easier than older models. Because of this flexibility, factories can upgrade their existing machinery without buying brand new systems from scratch, something that saves money while still getting good results in both manufacturing plants and robotic assembly lines. Built to handle tough conditions day after day, this connector keeps working reliably even when things get messy on the factory floor, so most engineers find it worth investing in for long term operations.

Installation Best Practices

Wiring Considerations for Legacy Systems

Getting familiar with how older systems are wired can really help prevent problems down the road, whether it's something going wrong operationally or actually damaging sensors. These days, most systems come with pretty complicated wiring setups that need good thinking through before getting started. When installing or maintaining things like inductive sensors or photoelectric sensors, having color coded wires and labels on all the connections just makes life so much easier. It cuts down on mistakes when setting everything up later on and saves headaches when trying to figure out why something isn't working right. Plus, this kind of organization pays off big time when it comes time to upgrade or replace parts. Take inductive proximity sensors for instance, the ones developed back in the day by companies like Pepperl+Fuchs still work great today if installed properly from the get go.

IP67 Protection for Harsh Environments

IP67 ratings basically mean sensors won't let dust in and can handle being submerged in water, which makes them great for tough industrial settings. Getting this kind of protection really matters because it stops equipment from breaking down, cuts down on those costly repairs, and keeps sensors working longer than they otherwise would. Think about places where there's constant spraying or areas where machinery gets used nonstop all day long. That's exactly where IP67 rated parts shine, keeping everything running smoothly without unexpected interruptions. Take the Series F31 Valve Position Sensors made by Pepperl+Fuchs for instance. These sensors have proven track record of lasting through rough conditions, which helps businesses avoid those frustrating shutdowns that nobody wants during production cycles.

Industrial Applications Enabled

Valve Position Monitoring in Pneumatic Systems

In pneumatic systems, inductive sensors play a key role when it comes to tracking where valves are positioned. They give really accurate feedback that helps automate processes better. Take the Series F31 from Pepperl+Fuchs for example these little guys have compact designs and electronic switching points that tell exactly where something is located. When companies install these kinds of sensors, they see improvements in how well operations run day to day plus things just work more reliably overall. Advanced sensing tech like this has become pretty essential in today's automated environments. What makes them stand out compared to old school mechanical limit switches? Well, there's no fiddling around with adjustments needed anymore. No more worrying about parts wearing down over time from constant metal fatigue either. That means longer lasting equipment without all those maintenance headaches.

Conveyor Belt Object Detection

Inductive sensors have become essential components in conveyor systems where they detect metal items moving along the belt. This helps keep track of materials properly and makes the whole operation safer for workers and equipment alike. When these sensors work correctly, they spot objects without any issues, which cuts down on wasted materials and saves time that would otherwise be spent sorting out problems. Factories and production lines across many sectors depend heavily on such sensors because they just plain work better than older methods. The fact that these sensors don't actually touch what they're detecting means there's less wear and tear over time too. For anyone running a plant floor or managing logistics operations, getting good results from inductive sensors translates directly into fewer headaches when things get busy during peak production periods.

These advanced sensors, such as those offered by Pepperl+Fuchs, demonstrate a superior level of precision in object detection, proving indispensable for industries that demand elevated performance and reliability in their operations.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES