Identify the Right Sensor for Level Monitoring Needs

Key Factors in Selecting Level Monitoring Sensors

Material Type: Liquid vs Solid Detection Requirements

Getting clear on what each material detection scenario actually needs makes all the difference in sensor selection. When dealing with liquids, proper operation usually means finding sensors with good sealing capabilities and appropriate pressure ratings that can handle whatever environmental changes come their way. Solid material detection tells a different story entirely though. These sensors must be able to cope with how tightly packed or loosely distributed the material is, since this directly affects measurement accuracy. Sensitivity settings matter too. A lot of folks run into problems when they try using liquid sensors for solid applications. The readings just don't match up because these devices aren't built for that kind of work. Sometimes simple adjustments fix things, but more often than not, getting the right type of sensor from the start saves time and headaches down the road.

Environmental Conditions and Sensor Durability

When looking at where to install these devices, we really need to check out the surroundings because things like changes in temperature, moisture in the air, and contact with various chemicals will affect how well they work and how long they last. Getting sensors that meet proper durability standards matters a lot too. Take those IP rating numbers seriously. They tell us about protection against stuff getting inside. An IP67 rated unit can handle both dust and being submerged in water, which makes sense when working in tough environments like industrial settings or outdoor locations where weather is unpredictable.

Accuracy Needs for Industrial Applications

In manufacturing environments across sectors like automotive and aerospace, precise measurements are essential for maintaining product quality standards while keeping operations running smoothly. When companies need to specify how tight those tolerances should be for different parts or components, getting this right makes all the difference between acceptable products and costly rejects. Many factories have seen tangible improvements after installing better sensor technology. These advanced sensors cut down on material waste during production runs and help machines operate at optimal speeds, which translates into real savings on the bottom line for plant managers who track these metrics closely.

Integration With Existing Control Systems

Ensuring sensors can easily integrate with existing control systems is paramount to seamless operations. This involves understanding communication protocols, such as Modbus or RS-485, that allow for compatibility with existing technologies. Such integration minimizes downtime and installation costs, thereby enhancing the overall return on investment.

Capacitive Proximity Sensors for Dual-Purpose Monitoring

AC M18-M12 Brass Capacitive Type Features

The AC M18-M12 brass capacitive sensor stands out because of its tough build and adaptability, working well whether detecting liquids or solids in all sorts of industrial settings. Built to last, this sensor handles tough conditions without breaking down, something manufacturers really need when they require constant monitoring over long periods. What makes this device special is how it does two jobs at once, which explains why so many factories choose it for tasks needing accurate readings while dealing with different types of substances throughout their operations.

AC M30 Plastic Cable-Type Sensor Benefits

The AC M30 plastic sensor brings real benefits because it's so light weight, which makes all the difference when setting things up in places that need frequent adjustments or quick installation. What stands out about this model is how versatile it actually is while still keeping costs down. It works great for tracking different kinds of parameters across many situations. Both big manufacturing plants and smaller workshops find value in these sensors since they handle multiple tasks without breaking the bank. Plus, despite being affordable, they don't compromise on either performance or dependability over time.

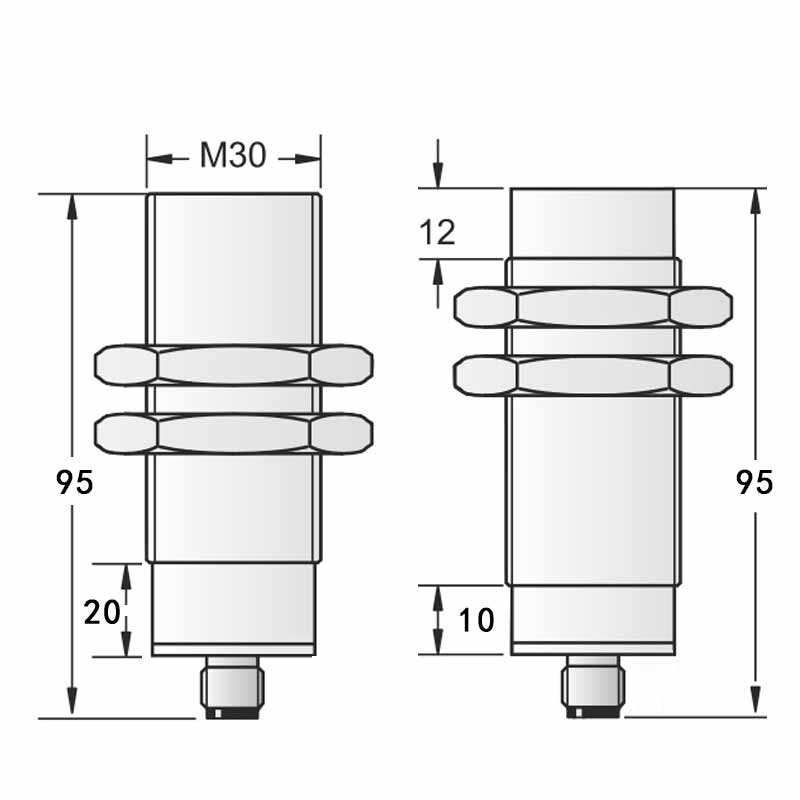

AC M30-M12 Compact Capacitive Solution

The AC M30-M12 sensor offers a compact alternative when bigger sensors simply won't fit into tight spaces. Designed with efficiency in mind, this little device packs some serious tech that boosts its ability to detect different materials accurately even under tough conditions that require constant watchfulness. Because it works so well in cramped quarters, many industries find themselves turning to this sensor whenever they need something that can monitor things precisely without taking up much room at all.

Comparing Sensor Technologies for Liquids vs Solids

Capacitive vs Inductive Proximity Sensors

Capacitive sensors work really well for picking up both liquids and solids because of how they're built to notice changes in material capacitance. They can handle all sorts of stuff, which explains why so many different industries have adopted them over time. Inductive proximity sensors tell a different story though. These babies are better at finding metal objects since they depend on electromagnetic fields to spot ferrous materials. When we look at actual performance differences, most field tests show capacitive sensors outperforming others when dealing with a wide range of materials, even those that aren't metal. For manufacturers trying to decide between sensor types, understanding these distinctions matters a lot. A plastics plant will need something completely different from what works in a steel fabrication shop, after all.

Laser Sensors for Precision Solid Level Measurement

Laser sensors stand out because they measure solid levels with incredible accuracy, something that matters a lot in situations where getting the numbers right is absolutely essential. Take manufacturing plants for instance, even tiny mistakes in measurements can cause major problems down the line. According to several industry studies from 2022, these sensors cut down on measurement errors by around 40% compared to older methods like mechanical gauges. Fewer errors means better reliability across production lines and smoother operations overall. That's why so many factories now rely on them for quality checks and process monitoring. The consistent readings they deliver day after day have become pretty much standard equipment in most modern manufacturing setups where precision just cannot be compromised.

Ultrasonic Solutions for Non-Contact Liquid Monitoring

Ultrasonic sensors work really well when we need to check liquid levels without touching them directly. Traditional methods often run into problems like getting contaminated or breaking down after repeated use. What makes ultrasonic tech special is how it bounces sound waves off surfaces to figure out where the liquid stands. No hands-on checking required! We've seen real world results too. One factory saved thousands on repairs after switching to these sensors. They just don't break as much and give better measurements overall. Especially useful in places where liquid levels keep changing throughout the day, like chemical processing plants or water treatment centers. For anyone looking at ways to monitor liquids without messing around with messy installations, ultrasonic options definitely deserve serious consideration.

Implementation Best Practices

Proper Mounting Techniques for Different Materials

Getting the mounting right makes all the difference when it comes to accurate and reliable sensor readings across different materials. For example, solid surfaces often need bracket mounts while flexible materials might require something else entirely. Most installation guides out there actually contain gold mines of information about what works best in tricky situations. Anyone working with sensors should take time to read through these manuals because they explain exactly how to avoid those frustrating false readings we've all seen before. Understanding these details isn't just theoretical stuff either it directly impacts whether our monitoring systems give us trustworthy data day after day.

Calibration Methods for Mixed-Phase Environments

Getting sensors properly calibrated matters a lot when they're used in places where both liquid and solid materials are present. The reason? These different states of matter behave so differently that calibration methods need special attention to get things right. For instance, liquid tends to flow while solids maintain their shape, which affects how sensors read measurements. Most sensor makers actually come with suggested schedules for checking calibrations regularly. This helps facilities stay on top of maintenance requirements and keeps equipment running smoothly day after day. When done consistently, this routine calibration work does more than just keep numbers accurate it helps sensors adjust better to all those changing conditions we see in real world settings with mixed materials, making sure readings remain trustworthy even as circumstances shift around them.

Maintenance Strategies for Long-Term Reliability

Good maintenance really makes all the difference when it comes to keeping sensors working properly over time. Most experts agree that checking equipment regularly and sticking to scheduled maintenance helps stop problems before they happen. We've seen this work across different industries where proper care keeps things running smoothly. When companies actually follow through on these basic checks, they end up spending less money fixing broken sensors and get way more use out of their investment. The bottom line? Taking care of sensor systems isn't just about avoiding headaches down the road, it's about building something that lasts and performs reliably day after day.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES