Inductive Proximity Sensors: Solving Complex Detection Challenges with Ease

How Inductive Proximity Sensors Tackle Detection Challenges

Electromagnetic Principles for Precise Metal Detection

Inductive proximity sensors basically work with electromagnetic fields to spot metal stuff nearby. What happens is pretty cool actually - the sensor creates this alternating magnetic field through a coil setup. Then when something made of metal comes close enough, it messes up the field pattern, which tells the sensor that metal is present right there. Most of these sensors operate somewhere around 10 to 70 kilohertz frequencies. That sweet spot lets them pick up different kinds of metals regardless of size or composition. Why does this matter? Well, in food processing plants these sensors save the day by catching any accidental metal bits before they end up in products. Automotive factories rely on them too, making sure all those tiny metal components get assembled correctly without missing anything critical during production runs.

Non-Contact Detection Technology in Harsh Environments

When dealing with really tough operating conditions, non contact detection tech like inductive proximity sensors becomes absolutely essential. We're talking about places where temperatures spike, pressure builds up, or there's just plain old dirt and grime everywhere. All these factors contribute to much higher failure rates when using regular contact based sensors. The beauty of non contact approaches is they completely sidestep physical wear issues and cut down on potential damage to both the sensor itself and whatever it's monitoring. Industrial facilities have found that inductive sensors stand out for their toughness. Field tests show these sensors fail far less frequently compared to traditional contact types, which means operators get better reliability over time and longer service life from their equipment despite all the harsh conditions they face daily.

Adaptable Designs for Industrial Integration

Inductive proximity sensors work great across many different industrial settings because they adapt so well to whatever setup they're placed in. The modular nature of these devices means companies can customize them pretty easily depending on what needs detecting. We see all sorts of shapes available too - think about those standard round ones alongside rectangle models, plus special editions built to handle really hot or cold environments. Take factory floors for example, where space constraints often require sensors that fit just right without taking up extra room. Plus, when it comes to meeting regulatory requirements, most manufacturers follow IEC and ISO standards. This isn't just paperwork stuff either; proper certification actually makes sure everything works safely within established parameters. That's why so many plants prefer these sensors when upgrading their current equipment.

Precision Positioning in CNC Machining

In CNC machining shops across the country, inductive sensors have become essential tools for getting those tight tolerances right. When manufacturers install these sensors, they're able to position workpieces with remarkable accuracy, something that matters a lot during operations such as turning, milling, and boring holes. The way these sensors work creates a kind of continuous check system that keeps everything running smoothly while making sure metal components are properly aligned before cutting begins. Take lathe work for example where even small deviations can lead to scrap metal piles growing fast and expensive tool wear. Real world data shows that shops implementing inductive sensing technology typically see error rates drop by around 30%, which translates into better finished products and fewer rejected batches on production lines.

Automated Assembly Line Quality Assurance

On modern assembly lines, inductive sensors play a key role in spotting problems before they become real issues, helping manufacturers stick to their quality requirements. These devices fit right into QA systems because they can detect metal components with remarkable accuracy. Take car manufacturing for instance – these sensors check if bolts are properly seated when building vehicles, which stops faulty cars from rolling off the line. Some factories report defect rates dropping by around 30% after installing these systems. When parts need to be positioned just so, these proximity sensors make sure everything lines up correctly. This not only keeps products meeting specs but also means fewer rejects and faster throughput across the factory floor.

Safety Monitoring for Heavy Machinery

Safety around heavy machinery gets a major boost from inductive sensors. These devices work in real time, so when something goes wrong like equipment overloading or unexpected objects getting too close, they kick in emergency stop systems before accidents happen. Construction sites and factories have been using inductive proximity sensors for years now to keep workers safe. Take automated forklifts as a good example. The sensors installed on these machines detect people walking too close or obstacles blocking paths, which makes the forklift stop automatically. This kind of technology has made workplaces much safer overall. Companies report fewer injuries and less downtime after installing these sensors, which means better productivity without compromising worker safety.

Material Sorting Systems in Recycling

Inductive sensors play a really important role in material sorting systems, especially within the recycling sector where they make a big difference. They can tell apart various materials pretty well, which means automated sorting works much better than when people have to do it manually. Since these sensors don't need physical contact, they respond quickly and handle things at high speeds. Recycling plants report that installing such sensors boosts the amount of recyclables recovered by quite a margin. When we automate sorting with accurate metal detection capabilities, not only does recycling become more efficient, but it also helps move us toward more sustainable ways of handling waste overall.

Immunity to Dust, Moisture, and Temperature Fluctuations

Inductive proximity sensors really shine when things get tough in industrial environments where other detection systems tend to break down or give inconsistent results. These sensors are built tough enough to handle all sorts of nasties like dust buildup, water exposure, and wild temperature swings without missing a beat. Take a look at manufacturing floors for instance they keep working just fine even when there's oil flying around or parts getting washed down, something that would mess up most optical sensors pretty quickly. The fact that they last so long under these rough conditions means companies don't have to replace them as often. According to industry data, facilities using these rugged sensors see maintenance needs drop by about 30%, which translates into real money saved over time while keeping production lines running smoothly through whatever comes their way.

Long-Term Reliability with Minimal Maintenance

A big plus for inductive proximity sensors is how reliable they stay over time compared to other types like electromagnetic or optical ones. These sensors don't really need much maintenance since there's nothing moving around inside them that can wear out. That makes all the difference when running factories or production lines where every minute counts. Some manufacturing plants have actually saved thousands on repair bills simply because these sensors last so long without breaking down. Factory managers we've talked to mention how frustrating it gets with regular sensors failing unexpectedly, but with induction models, they rarely face those kinds of problems during normal operations. The sensors just keep working day after day without giving anyone headaches.

High-Speed Response for Dynamic Processes

When things are moving at lightning speed in industrial settings, how fast inductive sensors react makes all the difference in running those dynamic processes smoothly. These sensors respond so quickly they basically eliminate errors during operations, which means less time spent fixing problems and more stuff getting made. What's really impressive about them is their ability to detect changes almost instantly, keeping up with even the most complex automated systems without missing a beat. Some recent studies point to factories seeing anywhere between 15-30% reduction in downtime after switching to these kinds of sensors. Beyond just saving time though, this speed helps maintain consistent workflows throughout the day. We've seen it happen ourselves in several manufacturing plants where output rates went through the roof once they implemented faster sensor technology across their assembly lines.

Q5 Square Inductive Sensor: Space-Efficient Detection

What makes the Q5 Square Inductive Sensor so special? Its sturdy square shape saves valuable real estate while still packing serious detection power. The compact form factor fits right into tight spots where bigger sensors wouldn't work, yet doesn't sacrifice any of the sensing capabilities. We see these sensors doing great work in places like assembly lines and material handling systems where every inch counts. They can spot even tiny metal parts accurately, which matters a lot when production speed is critical. Plus, the build quality holds up under tough conditions. These sensors keep working reliably whether installed near heat sources or in cold storage areas, something many competitors struggle with in extreme environments.

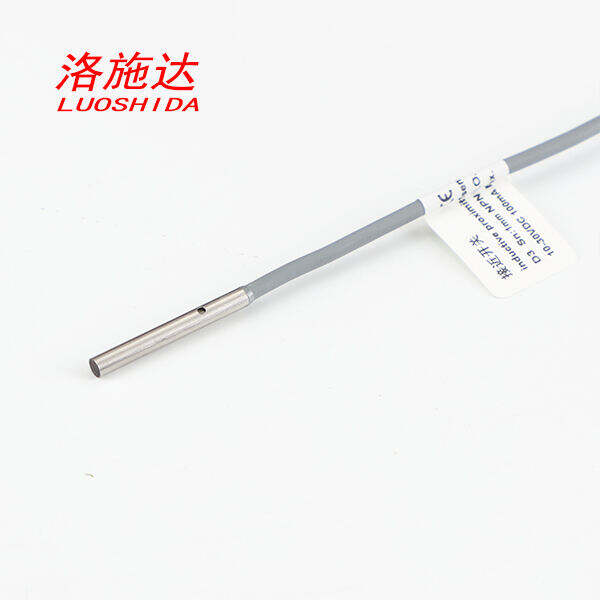

D3 Mini Inductive Sensor: Compact Cable-Type Operation

The D3 Mini Inductive Sensor was built to handle all sorts of different situations in factories and plants because of how small it is and the way it connects through cables. These little sensors work really well when there isn't much room to spare. Their tiny footprint means they can go into places where bigger sensors just won't fit. The whole thing comes with the cable already attached, so putting it in place doesn't take long at all. Most people who install these things love how sensitive they are plus the fact that they don't break easily even after years of use. They hold up pretty good in tough environments too, giving reliable readings without setting off alarms unnecessarily most of the time.

High-Performance Q5 Sensor for Robotic Integration

The Q5 Sensor really stands out when it comes to working with robots, bringing some pretty special features to the table for automating processes. What makes it work so well is how easily it connects to different robotic systems, which means machines can operate with pinpoint accuracy even when conditions change constantly. Built tough from the ground up, this sensor doesn't let users down over time, something plant managers care deeply about since every minute of machine downtime costs money. Real world tests at manufacturing facilities show these sensors making a real difference, with one factory reporting 30% faster cycle times after installation. Companies that have made the switch report fewer unexpected shutdowns and better overall output quality, factors that make all the difference in competitive markets where margins are thin.

Factors in Sensing Range and Target Material

Getting familiar with how different materials affect sensing distance matters a lot when picking out inductive sensors. These sensors work best with metal objects, but the actual detection range changes depending on what kind of metal we're talking about. Ferrous metals such as iron and steel generally give better results because they saturate more easily, which means the sensor can detect them from further away compared to non-ferrous options like aluminum or copper. Before making a purchase, it pays to think about which materials will be encountered most often during operation. Matching the right sensor to both the material being detected and required sensing distance makes all the difference in real world performance. A common mistake happens when someone grabs a sensor designed mainly for ferrous metals and tries to use it on aluminum parts instead. This mismatch typically leads to weaker signals and inaccurate readings, causing headaches down the line with production issues or equipment downtime.

Environmental Resistance and Mounting Considerations

Environmental resistance plays a major role in picking the right inductive sensors for real world applications. These sensors face all sorts of tough situations on factory floors including high heat, damp environments, and corrosive chemicals that come with regular maintenance work. Good quality construction materials along with protective coatings make these sensors last longer while keeping them accurate over time. Mounting matters just as much too. How the sensor gets installed makes a big difference in how well it actually works. Get the mounting wrong and problems start popping up fast. The sensor might pick up vibrations from nearby machinery, get knocked out of alignment during routine operations, or accidentally touch something it shouldn't. All these issues mess with signal strength and readings. That's why taking time to assess what kind of environment the sensor will be working in and choosing appropriate mounting solutions becomes so important for getting reliable results day after day.

Integrating with PLCs and Automation Systems

When we connect inductive sensors to PLCs (those Programmable Logic Controllers) within automated settings, it really boosts how well systems work and makes data much more accurate. Setting this up typically means getting the sensor talking to the PLC so it can handle data on the fly and keep everything running smoothly. What happens next is pretty cool actually these connected systems can make decisions automatically, tweak themselves when things change during production, and watch over operations much better than before. Since inductive sensors are great at spotting metal stuff accurately, putting them together with PLCs leads to more reliable production lines and overall better performance across the board. Look at what's happening in automotive manufacturing plants right now they've seen dramatic drops in machine downtime after installing properly integrated sensor systems, plus parts get made with far greater precision because of this setup.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES