Looking for a sensor for tight spaces? Try the separated mini inductive one!

What is a Mini Inductive Sensor?

Understanding inductive proximity sensors

Inductive proximity sensors work as non-contact devices that can sense metal objects without actually touching them. These gadgets operate based on electromagnetic induction principles, basically creating an electromagnetic field around themselves which helps detect when something metal comes near. Because they don't need physical contact to function, industries have adopted them extensively across manufacturing floors where automation is critical for both productivity and worker safety. Factories especially appreciate how these sensors cut down on maintenance costs since there's no mechanical wear from constant touching. From assembly lines to packaging systems, manufacturers rely heavily on this technology because it just works reliably day after day without breaking down unexpectedly.

How mini inductive sensors differ from standard sensors

Mini inductive sensors take up way less room than regular ones, which makes them perfect for cramped spots or small machines where there's just no extra space. Even though they're tiny, these little guys still deliver solid detection accuracy most of the time, sometimes even better than the bigger models depending on what they're measuring. The fact that they fit into tough places without losing any real function means engineers can install them almost anywhere needed. Factories have been putting them inside conveyor belts, robotic arms, and other tight areas where traditional sensors simply wouldn't work at all.

Benefits of Mini Inductive Sensors in Tight Spaces

Enhanced detection accuracy in confined areas

Mini inductive sensors work really well when space is limited or cramped, which makes them super useful in tight spots throughout manufacturing setups. Because these sensors are so small, they can get much closer to whatever needs detecting, which naturally boosts how accurate the readings end up being. That's why many factories rely on them for jobs requiring pinpoint accuracy like controlling robotic arms or managing tiny parts on assembly lines where getting the position right matters a lot for quality control purposes.

Compact design for space-saving integration

Mini inductive sensors take up very little room, which is why they work so well in cramped installation spots. Engineers often find themselves needing to squeeze these tiny sensors into places regular sized ones simply won't go, especially inside industrial machines where every millimeter counts. Because of their small size, complex automation systems stay fully functional while still saving valuable real estate on production floors. For manufacturers dealing with limited workspace, this means better overall system performance without sacrificing measurement accuracy or operational speed.

Robust performance in demanding environments

Mini inductive sensors can handle pretty tough situations out there in the field. These little guys stand up to all sorts of rough treatment like extreme heat and constant shaking from machinery. Industrial workers rely on them day after day because they just keep working without giving problems. That means less time spent fixing equipment and more time getting actual work done. The durability factor is what makes these sensors so valuable in places like car factories and production lines. After all, when machines are running nonstop, having sensors that don't break down under pressure becomes absolutely essential for keeping operations rolling smoothly.

These proximity sensors, especially inductive ones, give feedback without making contact. This matters a lot for safety reasons when machines are running automatically, plus it cuts down on parts wearing out over time, so equipment lasts longer. What makes them really useful is how they fit into tight spots where other sensors just wouldn't work. The result? Machines perform better while taking up less room on factory floors or wherever they're installed.

Applications of Mini Inductive Sensors

Industrial Automation and Robotic Arms

In industrial automation setups, mini inductive sensors have become essential for detecting objects with pinpoint accuracy. When attached to robotic arms, these little devices make sure components get positioned just right and movements happen without hiccups. Factories report better productivity numbers when using these sensors because mistakes drop significantly during operations on assembly lines or when robots perform specific tasks. Most manufacturers now consider these sensors fundamental equipment for any serious automated production environment.

Conveyor Systems for Material Handling

Small inductive sensors play a really important role in conveyor systems when it comes to figuring out if something is there or not, which keeps materials moving properly through the system. These little devices actually help stop those annoying jams and alignment problems that can bring everything to a halt. Take a look at warehouses or factories anywhere and chances are good they're using this tech behind the scenes. Logistics centers rely heavily on them since packages need to travel from one point to another without getting stuck. Same goes for food processing plants where products move along belts at high speeds. Without these sensors keeping track, whole production lines would come grinding to a stop regularly, causing all sorts of headaches for managers trying to meet deadlines.

Automotive Industry for Component Detection

The automotive industry relies heavily on mini inductive sensors for detecting components throughout assembly lines. These little devices help make sure parts go exactly where they need to be, which naturally boosts both quality and how reliable cars end up being. Most often we find them working behind the scenes in really important spots such as engines and braking systems. The accuracy they bring to these positions matters a lot when it comes to keeping vehicle production standards high across the board.

Key Features to Look for in Mini Inductive Sensors

High Detection Accuracy

Choosing the right mini inductive sensor means putting detection accuracy at the top of the list. Good accuracy matters a lot when working with precision tasks across industries like manufacturing plants or automated assembly lines. These accurate sensors help keep operations running smoothly, cut down on mistakes, and ultimately maintain product quality throughout production runs. Before making a purchase decision, take time to look closely at technical specs. Pay particular attention to things like how consistent readings are (repeatability) and just how far away objects can be detected (sensing distance). Getting this information straight will help determine if the sensor actually fits what needs to get done on the factory floor.

Wide Operating Temperature Range

When choosing sensors, look for ones that work well through different temperature ranges. The ability to handle various temps means these devices can be used almost anywhere, from hot industrial settings like steel mills down to cold storage facilities outside. A sensor that keeps performing reliably no matter what the heat does makes all the difference in real world applications. Check the spec sheet for temperature limits before buying anything. Knowing this info helps prevent breakdowns when things get too hot or too cold during regular operations.

Easy Installation and Maintenance

Mini inductive sensors that install quickly and need little upkeep can really cut down on setup time and keep production running smoothly. The plug and play feature makes connecting them to current equipment straightforward, which saves headaches during installation. Sensors built with tough housings stand up better to rough environments too, so there's less chance of needing repairs or replacements down the road. All these factors combine to save money over time while keeping operations efficient without constant stoppages for maintenance work.

Top Mini Inductive Sensors for Tight Spaces

Q5 Square Inductive Sensor

The Q5 square inductive sensor stands out because of how small it is yet still delivers top performance, which makes it great for jobs that need accurate and dependable sensing. The sturdy case can handle tough conditions on factory floors, and since the unit itself isn't big at all, it fits into places where bigger sensors just won't go. We see these sensors popping up everywhere from assembly lines in manufacturing plants to packing machines in food processing facilities, not to mention their role in modern car production where every millimeter counts. For engineers dealing with limited installation space, this little workhorse offers a solution that doesn't compromise on quality despite its diminutive size.

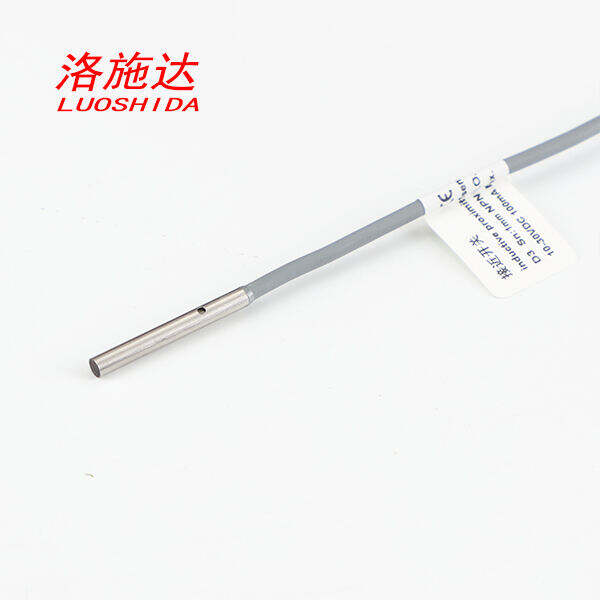

D3 Mini Inductive Sensor with Cable Type

The D3 mini inductive sensor works really well in cramped areas because of its flexible cable design that makes installation simple and keeps the electrical connections solid. These sensors pick up signals with good accuracy and stay consistent over time, so they're great for things like automated assembly lines or sorting materials on production floors. What makes this small sensor stand out is how tough it is against wear and tear while still being easy to set up. Many factories have found that switching to these compact sensors helps them run their operations smoother without needing constant maintenance checks across different manufacturing setups.

How to Choose the Right Mini Inductive Sensor

Consider the sensing distance

Sensing distance plays a major role in picking out the right mini inductive sensor for any given situation. Getting this measurement right matters because it directly affects how well the sensor can detect objects accurately. When looking at options, sensors whose range matches what's needed tend to work better overall. For bigger installations or complicated setups though, sometimes going with something that has a longer reach makes more sense. Proper selection based on these factors leads to smoother operation without unnecessary complications down the road.

Evaluate the housing material

Picking the correct housing material really matters when it comes to how long a sensor will last and how well it performs. For instance, if working outdoors where corrosion might be an issue, stainless steel could work best. Plastic housings tend to be lighter and cheaper but don't hold up as well in harsher conditions. Nickel plated brass strikes a nice middle ground between cost and protection. The differences matter because some materials simply cannot handle extreme temperatures or chemical exposure found in many factories and processing plants. A good quality housing extends sensor life significantly while keeping them safe from damage caused by daily operations in tough industrial environments.

Check for compatibility with your system

Getting along with what's already there matters a lot when it comes to avoiding headaches down the road. When picking out a sensor, take a good look at things like what kind of power it needs, how it sends its signals, and whether it can talk to whatever equipment is currently in place. Doing this check upfront saves plenty of trouble later on when trying to get everything working together. Most folks find that taking these steps makes installation go much smoother and keeps their whole setup running efficiently without unexpected hiccups in real world situations.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES