What are the main types of photoelectric sensors?

In automation systems, photoelectric sensors detect objects without touching them. They are used to see whether a product is loaded onto a conveyor belt, check if a door is properly closed, or even used in factory automation to see if a box is packed. Different photoelectric sensors are used for different uses. Knowing these differences is important when sourcing photoelectric sensors for your electronics plant or for a food packaging facility. Let’s learn the different types of photoelectric sensors, how they function, and their common applications.

Through Beam Photoelectric Sensors: Reliable for Long Distance Detection

Through beam photoelectric sensors are the simplest and most dependable types of sensors. They detect objects using a light beam and a light receiver. The transmitter and receiver are used in pairs. The transmitter emits a light beam in the infrared spectrum. The receiver waits to catch the beam and is placed at the other side of the emitted beam.

When nothing is blocking the way, the receiver captures the light beam, and the sensor remains in its “normal” state—perhaps sending a signal to a conveyor to keep moving. But when an object passes between the transmitter and receiver, it blocks the beam. The receiver detects the loss of light, and the sensor alters its signal. For example, it might tell the conveyor to stop, a counter to increase, or a robot arm to pick the object.

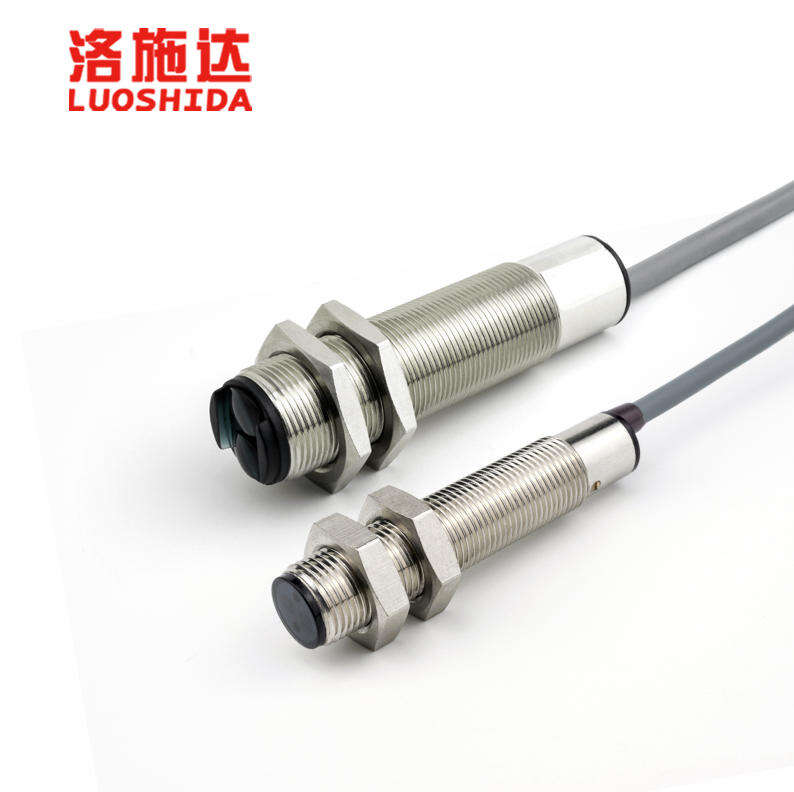

Through beam sensors are known for their long-range capabilities. They can operate anywhere from a few centimeters to several meters, and some even go further, like the LUOSHIDA FCD-XXYYYAB series, which boasts a detection range of 100 meters when marked “M.” This sensor is reliable, as it does not require the object to reflect light, only to block it. This means that it can handle almost any material, including dark or non-reflective ones, such as black plastic parts or metal sheets.

Through beam sensors can be found where distance measuring precision is required. In a car parts factory, for example, they can count metal gears that are in motion on a long conveyor belt. In a logistics center, these sensors can identify large containers as they go through a sorting tunnel. Since they are not impacted as much by dust or dirt (the beam can cut through light debris), they are also a good choice for dirty environments like woodworking shops or metal-cutting areas. LUOSHIDA also considers the rough use in industrial environments when designing through beam sensors, providing durable casing.

Diffuse Reflective Photoelectric Sensors: Simple for Close-Range Tasks

If you lack space for two separate parts (transmitter and receiver), a diffuse reflective photoelectric sensor might serve the purpose. This type is an all-in-one device—both the transmitter and receiver are in the same housing. Instead of sending a beam to a separate receiver, it sends light to the object, and then waits to receive the light that bounces back (reflects) off the object.

Let's say there is a sensor placed above a conveyor belt that moves small plastic bottles. When a bottle is not placed below the sensor the transmitter’s light is not hitting anything and the receiver does not get any reflected light. So the sensor is “off.” When a bottle is placed below the sensor the light hits the bottle and is reflected back to the sensor. The sensor is activated and the received light is reflected and switched back and the sensor is on. This is activated and sent to the conveyor control system. This may tell the system to slow down to fill the bottle or check if the bottle is the right size.

Close-Range Detection:Diffuse reflexive sensors detect objects effectively at a few centimeters to a meter range. They are quite easy to install because you only need to set one sensor instead of a pair. They need objects to reflect light so it is best used on light colored, smooth surfaced objects. Dark colored, rough surfaced objects, like pieces of black foam, rubber and rough rubber, may not reflect enough light, and therefore may not be detected, resulting in false readings. Some models, like LUOSHIDA's, have adjustable sensitivity so you can increased sensitivity to detect darker objects, or decrease sensitivity to avoid detecting small debris that may be a nuisance.

Compact Sensor Uses:In a food packaging plant, diffuse reflexive sensors detect if a candy bar is in its wrapper before sealing. No need for a separate receiver on the other side of the wrapper line. They are used in many space restricted environments. For instance, in a electronics factory, compact diffuse sensors can be used to check if a microchip is properly placed on a small circuit board.

Retro Reflective Photoelectric Sensors: Balancing Distance and Simplicity

Retro reflective photoelectric sensors, or “retro sensors,” fill the gap between through beam and diffuse reflective sensors. They have one housing, like diffuse sensors, which contains both the transmitter and the receiver, but they require a separate reflective plate (called a “retro reflector”) placed directly across from them. The transmitter sends light to a reflector, which bounces it straight back to the receiver, like a mirror.

Here’s the process: when there is no object in the way, the reflector sends light back to the receiver, and the sensor is “on.” When an object passes between the sensor and the reflector, it blocks the light from reaching the reflector and the receiver, or scatters it and the receiver, so the receiver doesn’t get the reflected beam. The sensor then switches off, which triggers an action, like stopping a machine or alerting an operator.

Retro reflective sensors come with three major advantages. First, they are capable of detecting objects at a greater operational range, around 20 meters, than diffuse sensors, while still avoiding the two-part setup of through beam sensors. Second, retro reflective sensors are more reliable than diffuse sensors for reflective objects. This is mainly because the retro reflector is built to powerfully bounce back the light, meaning the sensor won’t be fooled by the object's own reflection, even shiny ones like a metal can. Finally, retro reflective sensors are great for detecting clear objects like glass bottles or plastic bags. Diffuse sensors are actually quite poor at detecting these objects because while they block the beam to the reflector, diffuse sensors rely on backscatter to detect the object.

Retro reflective sensors are commonly used in beverage bottling plants. For example, they can be installed beside a conveyor that transports glass bottles, with a reflector mounted on the other side. When a bottle passes, the sensor beam is blocked, and the sensor signals the filling machine to start the soda pour. These sensors can also be used in factory door systems. For example, one sensor can be mounted on one side of the door and the reflector on the other so that the sensor can detect a person and keep the door open. LUOSHIDA sensors come with easily mountable ready to use reflectors.

Factors that Matter Most

Now that you know the main types, how do you choose the right one for your specific needs?This involves factors like how far you have to detect objects, the materials of the objects, and the amount of space you have to work with. Let’s look at the factors that will matter most in your situation.

To start, think about detection distance. If the distance to be covered is long, say 10 meters for a conveyor, then a through beam sensor is your best option. If the distance is under a meter and you have limited space, a diffuse reflective sensor is your best option. If you want something in between, a retro reflective sensor works for most cases. LUOSHIDA provides good product documentation, including the FCD-XXYYYAB series, which details the distance settings for each sensor, so you should be able to choose the most appropriate one for your needs. All the documentation is available online for ease of access.

Next, think about what the object is. Consider what a sensor will be detecting. Is the object dark, reflective, or transparent, and will it reflect or absorb light?The object can be opaque but through beam sensors just require the object to block light. Diffuse sensors reflect light, so light colored and shiny objects work best, but I have seen settings that allow for the detection of light colored objects. Retro reflective sensors work very well for transparent objects, much more than diffuse sensors. An example of this is detecting clear plastic containers.

Next, assess the surroundings. Is the environment dusty, wet, or overly bright?Through beam and retro reflective sensors can better handle ambient light because they focus their light. Diffuse sensors may struggle in bright areas, but sensitivity adjustment tends to solve the problem. All three options can come in durable casings designed for harsh environments, such as food processing plants or metal shops, including some with IP ratings for protection against dust and water.

Lastly, think about the installation process. Through beam sensors require you to mount two parts (transmitter and receiver) in perfect alignment, which takes a little longer, but it pays off for long distances. Diffuse and retro reflective sensors only have one main device, making their installation faster. Retro reflective sensors come with a reflector mount, but most come with adhesive or mounting brackets that make it easy.

Whichever type you pick, it’s good to verify the certifications. LUOSHIDA’s photoelectric sensors follow the standards EN 61000-6-3 and EN 61000-6-1 for electromagnetic compatibility (EMC) which means they will not be affected by other machines such as motors or welding equipment. They also have RoHS certification meaning they do not contain any dangerous materials which is crucial for the electronics and medical device manufacturing industries.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES