Fiber Amplifiers Boost Signal Integrity in Noisy Environments

How Fiber Amplifiers Maintain Signal Clarity in Noisy Environments

Optical Amplification Without Electrical Conversion

Optical amplifiers boost signal strength while keeping light signals in their original form, so they don't lose quality during processing. The way these devices work depends on something called stimulated emission that actually strengthens the optical signals right away. That's pretty different from older methods that required turning light into electricity first. Since there's no need to switch to electrical signals, these amplifiers cut down on noise and other kinds of interference. For places where electromagnetic interference (EMI) is a big problem, this makes all the difference. Signals stay much clearer and stronger when things get tough, unlike regular systems that often break down completely under similar conditions.

Additionally, the absence of electrical conversion significantly minimizes the footprint of amplification systems. When an optical signal is boosted without change to its inherent form, it eliminates various conversion-induced inefficiencies, making it a streamlined solution for long-distance high-capacity data transmission.

EMI Immunity Through Light-Based Transmission

One of the big advantages of fiber optics is their natural resistance to electromagnetic interference, which makes them really good at keeping signals strong in places where there's lots of EMI around. Studies have shown time and again that fiber optic systems keep delivering clear signals even when faced with major outside disruptions, making them much more reliable than other options for consistent communication. The reason light based transmission works so well compared to old school copper cables comes down to how they actually work. Instead of using electricity like copper does, fiber optics send information through light pulses. Since these light signals aren't affected by the same kinds of interference that plague copper wiring, data keeps flowing smoothly without interruption, no matter what's happening in the surrounding environment.

Optical fiber cables work really well for communication in places where electromagnetic interference can't be avoided, think about things like airplanes, military installations, or busy city areas full of all sorts of electronic gadgets. Regular copper wires just don't cut it there though. The problem is that those pesky electromagnetic fields mess with the electrical signals running through copper, which either slows things down quite a bit or completely stops the signal from getting through. That's why so many critical systems have switched over to fiber optics instead.

Minimizing Signal Loss in High-Interference Zones

Fiber amplifiers use various approaches to cut down on signal loss, particularly where there's lots of interference going on. They work with stuff like wavelength division multiplexing and boosting signals just right so everything works better. The results? Much better performance numbers when we look at how well they actually function. Take erbium-doped fiber amplifiers (EDFAs) for example. When installed in those tricky spots with all the noise, they keep the signal quality intact across longer distances than what would normally happen if left unchecked. This matters because without proper amplification, data transmission gets messed up pretty quickly in these problematic areas.

The way we deploy equipment makes all the difference in getting the most out of our systems. When setting up network infrastructure, putting fiber amplifiers in key spots really matters. Think about long stretches of cable or areas close to things that might interfere with the signal. These placements help keep everything running smoothly. The good news is this approach works across different environments too. Signals stay strong even when outside factors try to weaken them. Companies that combine smart amplifier placement with careful planning of their network layouts find they can tackle those tough high-interference areas without much trouble. This means better performance overall and fewer headaches down the road with communications staying stable and dependable.

Critical Advantages of Fiber Amplifier Technology

Long-Distance Signal Preservation

Fiber amplifiers make it possible to send data over really long distances without the signal getting all messed up along the way. What makes them special is their ability to boost the actual light signal right there in the fiber optic cable, instead of having to switch it back and forth between light and electricity. The telecom companies have been seeing this work wonders in practice, especially when signals need to travel thousands of kilometers through undersea cables or across continents. Broadcasters depend heavily on these amplifiers too because they keep the quality of TV signals consistent even when transmitted from satellite to earth stations hundreds of miles apart. Without fiber amplifiers, maintaining those high speed connections would be nearly impossible for most modern communication networks.

High Bandwidth Capabilities for Data-Intensive Tasks

Fiber amplifiers pack serious bandwidth capacity that meets the needs of applications needing lots of data movement. The tech really shines in areas such as HD video streaming services, big data centers running cloud platforms, and even competitive online games where lag matters. With all that bandwidth available, data moves fast across networks and handles huge amounts of traffic without breaking a sweat. According to industry reports from last year, companies that implemented fiber amplifier systems saw noticeable improvements in their network performance metrics. Faster access speeds mean happier customers when they stream movies or download files, plus businesses run smoother operations day to day. That's why more organizations are turning to fiber amplification solutions as part of their infrastructure upgrades these days.

Low Noise Operation Compared to Traditional Amplifiers

Fiber amplifiers beat traditional electrical ones mainly because they produce far less noise. When working with light instead of electricity, these devices keep unwanted interference to a minimum, which means cleaner and better quality signals overall. Research indicates that this quiet operation matters a lot in areas needing precise measurements, think things like lab equipment or hospital diagnostic tools. For scientists running experiments or doctors relying on test results, keeping those signals pure makes all the difference between good data and garbage readings. The fact that fiber amps run so quietly doesn't just make signals clearer though it actually opens doors to using them in places where even tiny amounts of electrical noise would mess everything up.

D3 Mini Inductive Sensor for Noise-Resistant Systems

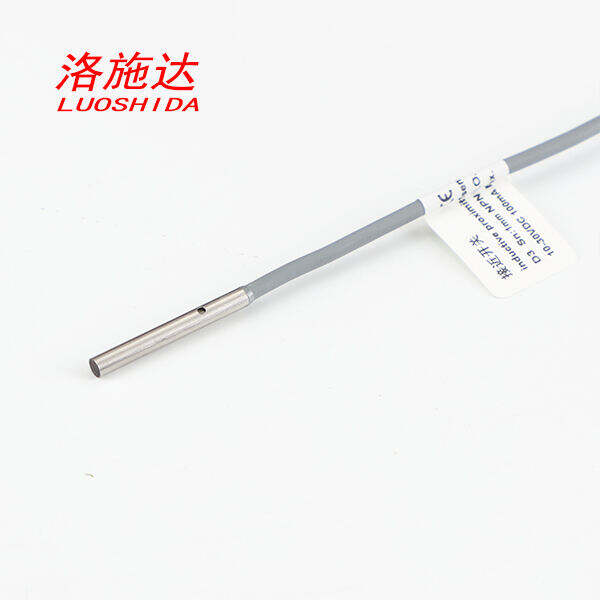

Compact Design for Tight Industrial Spaces

The D3 Mini Inductive Sensor has a really compact design that works great when there's just not much room in industrial settings. These little guys can squeeze into places where regular sensors simply won't fit, giving installers a lot more options when setting things up. Take automation plants or packaging lines for instance they need equipment that doesn't take up too much space while still getting the job done right. The sensor's tiny size means it slips easily into tight spots within machinery, which actually helps improve workflow efficiency especially in operations needing both accuracy and quick adjustments on the fly.

Inductive Sensing in Electromagnetically Noisy Areas

Inductive sensing tech really shines when dealing with all that pesky electromagnetic noise so common in factories and workshops. Take the D3 Mini for example these kinds of sensors work great without needing physical contact, which means they keep performing reliably even when there's lots of electrical interference around. Manufacturing floors and production lines benefit especially from this feature since signals need to stay accurate between all those machines and other electronics buzzing away. We've seen plenty of real world situations where these inductive sensors beat out regular ones hands down, staying dependable and efficient no matter how messy the electromagnetic environment gets on site.

Durable Construction for Harsh Environment Reliability

Built with toughened stainless steel housing and reinforced circuitry, the D3 Mini Inductive Sensor stands up to rough treatment in factory floors and outdoor installations alike. Dust won't penetrate its sealed casing, water droplets roll right off, and vibrations from nearby machinery barely register on this little workhorse. Maintenance teams across manufacturing plants and mining operations have found these characteristics invaluable over time. When sensors last longer between replacements, plant managers see real savings in both money and lost production hours. Industry reports consistently show that facilities investing in rugged sensing tech spend about 30% less on repairs compared to those using standard models. For companies running automated assembly lines or operating heavy earthmoving equipment, this kind of durability translates directly into bottom line improvements month after month.

Integrated Solutions for Industrial Applications

Combining Fiber Amplifiers With Proximity Sensors

When combining fiber amplifiers with proximity sensors, industrial communication systems get a real boost in performance. Fiber amplifiers basically make signal transmission work better, which means things run more efficiently overall. Most people know proximity sensors as those devices that spot objects without actually touching them, and they perform much better when paired with fiber amplifiers because signals stay clear over longer distances. Take an automotive assembly line for instance where this combo makes all the difference in tracking parts movement throughout the facility. The bonus here is reduced signal interference too, so everything keeps running smoothly even when surrounded by heavy machinery and other electromagnetic noise common in factories.

Case Study: Automated Manufacturing Signal Stability

Factories working with automated manufacturing have seen better signal stability since they started using fiber amplifiers. One factory actually combined these amplifiers with their old proximity sensors last year and saw way less signal loss while running their production lines. The difference was pretty noticeable too. Their machines ran nonstop most days instead of stopping every few hours for fixes. Money savings came in another way too. Maintenance teams didn't need to spend so much time fixing signal problems anymore. Looking at numbers from that factory's records shows around 30% boost in how efficiently they run operations. For plant managers dealing with tight budgets, this kind of tech integration makes real world sense beyond just theoretical improvements.

Future Integration With Photoelectric & Laser Sensors

The coming together of fiber amplifiers with various types of sensors including photoelectric and laser models promises major changes across industrial sensing operations. With ongoing tech developments, manufacturers should expect these sensor systems to become increasingly accurate over time, thanks largely to what fiber amplifiers bring to the table. What does this mean practically? More advanced network setups where multiple sensors work together seamlessly, sending information almost instantly without delays. We're also seeing progress in how photoelectric sensors function at their core level while laser distance measurement tech continues evolving rapidly. These advancements aren't just theoretical either they're already starting to impact real world manufacturing processes. When paired properly with fiber amplification technology, companies report better control over resources, fewer production stoppages, and overall factory floors that operate much more intelligently than traditional setups from just a few years ago.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES