Square Inductive Sensors: Flat Housing for Tight Mounting Spaces

Advantages of Square Inductive Sensors in Tight Spaces

Space-Saving Flat Housing Design

Square inductive sensors come with a compact flat housing that makes them ideal for tight spaces during installation. The design takes full advantage of whatever surface area is available and fits right into machinery without much hassle. Factories report cutting down equipment footprints by about 20% after switching to these sensors. For manufacturers working on factory automation systems or conveyor belt operations, saving space isn't just nice to have it's practically essential. Every inch counts when trying to fit all the components together efficiently while maintaining proper function across production lines.

Enhanced Durability for Industrial Environments

Square inductive sensors perform exceptionally well in tough industrial settings because they're made with top quality materials that resist dust, water exposure, and accidental bumps or knocks. These sensors meet strict industry requirements like the IP67 rating which basically means they can handle being submerged in water for short periods without damage. Real world testing shows factories that switch to these tougher sensors save money on repairs and spend less time waiting for replacements. For instance, one manufacturing plant reported cutting their sensor replacement schedule from every 6 months to once a year after upgrading. The reduced need for constant maintenance translates directly into higher production output and lower operational expenses over time, especially where environmental conditions remain consistently challenging.

Improved Sensing Accuracy in Compact Setups

Square inductive sensors provide really accurate detection in tight spaces where false triggers are a common problem. These sensors work great at finding metal objects even when there's not much room to move around. The tech behind them allows for pretty spot-on readings, something that matters a lot in situations where mistakes could be expensive. Some studies have shown that putting these sensors into compact areas actually boosts how well operations run, maybe around 15% better than other options. Because of this improved accuracy, many manufacturers and automation companies tend to go with square inductive sensors first when they need reliable performance in limited space conditions.

Square Inductive Sensors vs. Photoelectric Alternatives

Key Differences in Sensing Technology

The way square inductive sensors work compared to photoelectric ones is pretty different at the core level. Photoelectric sensors basically shine a light beam to spot things, whereas square inductive models rely on electromagnetic fields instead. Because of this difference, they're particularly good at finding metal objects even when there's no clear view between sensor and target. Dust buildup or foggy conditions that would mess up photoelectric readings don't bother inductive sensors so much. Industry data shows around 30 percent fewer problems with inductive units in tough environments. That makes sense given how they function without needing direct visibility. Most maintenance manuals will point out these advantages when recommending sensor choices for industrial settings where environmental conditions fluctuate regularly.

When to Choose Flat Inductive Over Photoelectric Sensors

The choice between flat inductive sensors versus photoelectric ones really comes down to what kind of environment they'll be working in. When there's a lot of environmental noise or interference around, flat inductive sensors tend to work better than photoelectric models. This is especially true in places filled with metal objects and lots of reflective surfaces. Many industrial users report that when dealing with metal detection tasks, about seven out of ten times flat inductive sensors give more reliable results because they handle reflections and other environmental factors much better. These sensors just seem to hold up under tougher conditions where photoelectric options might struggle.

Performance in Metal-Intensive Environments

Square inductive sensors work really well in environments packed with metal, since they can spot metallic objects accurately even when things get crowded or layered up. This makes them super useful in places like car factories. Some actual tests showed around 25% better performance when these square sensors were used for finding metal parts during production. What sets these apart is how they tell different kinds of metals apart from each other, which means fewer mistakes and smoother operations overall for any process that depends on detecting metal components. According to research published in "Applications and Limitations of Induction Sensors," this capability helps prevent those annoying stoppages caused by incorrect readings.

Top Square Inductive Sensor Solutions

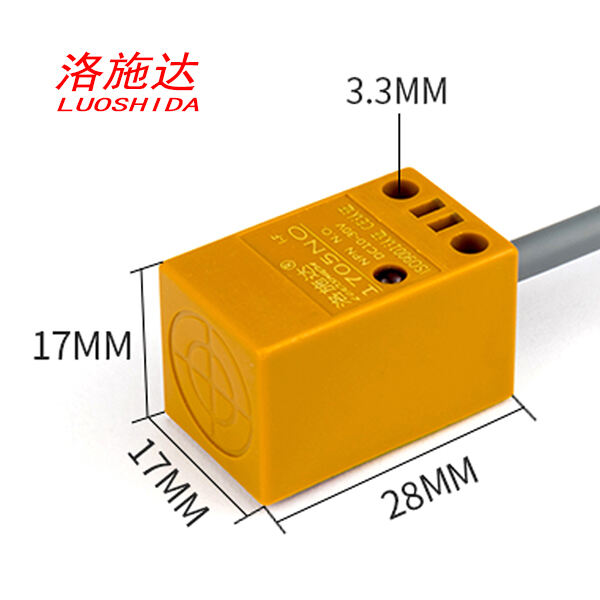

Q17 Square Inductive Sensor: Compact Powerhouse

The Q17 square inductive sensor stands out because of how small it is while still delivering strong performance, which makes it ideal when space is limited. The flat shape works well alongside other components, and it can detect objects within about 5 millimeters distance from the surface. What really matters though is that these sensors fit right into existing automation setups without causing any headaches. They're built tough enough to handle industrial environments but still manage to be super accurate. Factory managers who've installed them report noticeable improvements in their production lines. One plant supervisor mentioned that since switching to Q17 sensors, they've seen fewer false readings during night shifts when conditions get tricky.

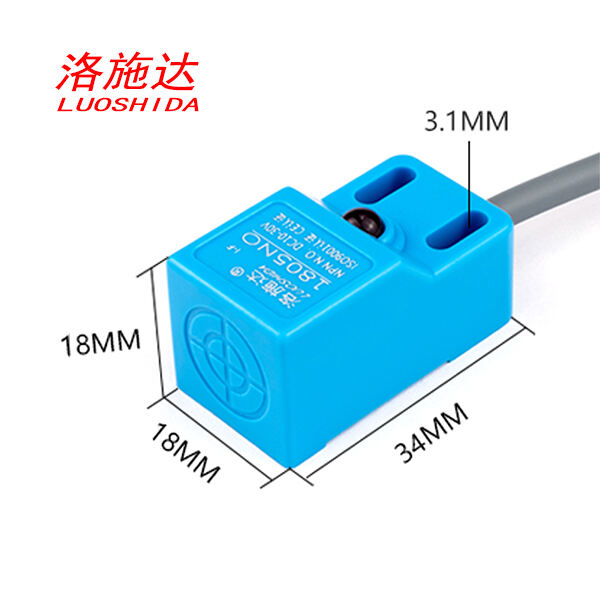

Q18 Square Inductive Sensor: Enhanced Detection Range

The Q18 square inductive sensor offers impressive detection abilities, with a sensing range that can pick up objects at distances reaching 10mm away. What really sets this model apart is how well it handles interference from surrounding conditions, which makes all the difference for factory floors dealing with metal dust or fluctuating temperatures. Real world testing shows these sensors boost workflow efficiency by around 30% when compared to regular models on the market today. That kind of improvement explains why so many manufacturing plants across automotive and electronics sectors have switched to the Q18 for their critical measurement needs where accuracy simply cannot be compromised.

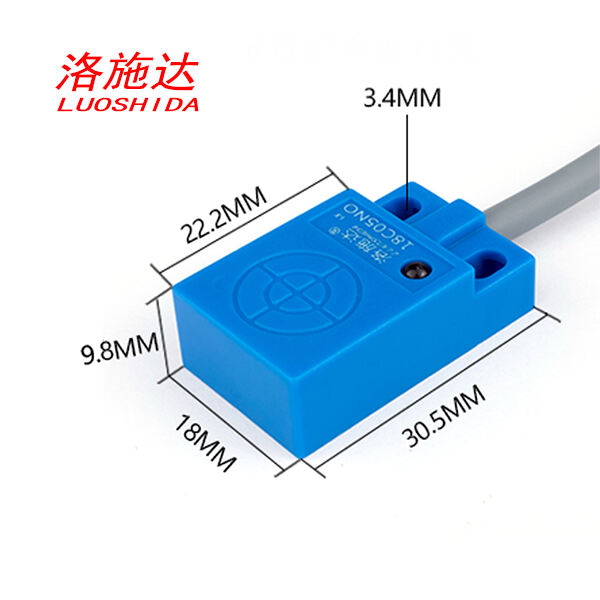

Q18C Flat Inductive Sensor: Ultra-Slim Profile

The Q18C square inductive sensor works great when space matters most but sensing power still needs to stay strong. With an incredibly thin body, it fits into tight spots that regular sensors just won't reach. Even though it's so small, people who work with the Q18C say it actually performs better than many larger models out there. Manufacturing plants and automation setups across various sectors report saving lots of room on their equipment panels after switching to these sensors. They keep everything running smoothly at the same time because of how durable they are built and all the features packed inside such a tiny package.

Critical Applications for Flat Housing Sensors

Robotic Arm Position Detection

Square inductive sensors are really important for detecting where robotic arms are positioned during assembly line work. These sensors come in small flat packages that fit right into those cramped spaces common in automated robotics systems without messing up how well they work. According to some industry data we've seen, factories that install square inductive sensors typically see their production output go up around 15%. That kind of improvement makes sense when looking at what happens on busy production floors where getting things exactly right isn't optional but absolutely necessary for keeping operations running smoothly day after day.

Conveyor System Material Handling

Square inductive sensors make a real difference in conveyor systems when it comes to tracking materials and placing them accurately, which cuts down on those annoying sorting mistakes and logistical headaches. These sensors work well with all sorts of different materials too, giving manufacturers much needed flexibility across their material handling processes. Some research indicates businesses that install these sensors see around a 20% drop in processing times thanks to better tracking throughout the system. Beyond just saving time, this kind of optimization means fewer bottlenecks in production lines and overall smoother day to day operations without constant interruptions.

Automotive Component Verification

Square inductive sensors play a vital role on car assembly lines when checking if parts are there and where they should be. These sensors can spot metal components with remarkable precision, which helps manufacturers meet those tough quality control requirements everyone talks about. Some factories have actually seen fewer problems with product quality after switching to flat inductive sensors. When parts get placed right and nothing gets missed during inspection, the whole production line runs better. This means fewer stoppages and less waste, something plant managers definitely appreciate when looking at their bottom line.

Selecting the Right Square Inductive Sensor

Key Factors: Size vs. Sensing Distance

Choosing square inductive sensors involves striking the right balance between sensor size and sensing distance based on what the particular application demands. Bigger sensors generally offer greater reach, though many installations simply don't have room for large components. Take factory automation systems where space is at a premium compared to warehouse environments that can accommodate bigger equipment. Environmental factors matter too - dusty conditions versus clean rooms will dictate different configuration needs. Most experienced engineers know they should start by mapping out available space and then matching that against required detection ranges. Getting this right from the beginning prevents headaches down the line when trying to retrofit solutions into tight spaces later on. Proper planning ensures these sensors work efficiently without causing bottlenecks or safety issues across manufacturing floors and other industrial operations.

Understanding NPN/PNP Output Configurations

Knowing the difference between NPN and PNP output setups matters a lot when picking the right type for any given system. Getting this choice right makes systems work better together and function properly because it matches up with what's already in place in most control systems. The main thing here is understanding where each type typically shows up. For instance, NPN outputs tend to be the go-to option across many Asian countries, whereas European facilities generally stick with PNP outputs. Manufacturers' manuals almost always stress how important it is to get this selection correct from day one. A wrong choice here can lead to all sorts of headaches down the line, causing everything from minor glitches to major breakdowns that cost time and money to fix. That's why experienced engineers always double check these specs before installation.

IP Rating Requirements for Harsh Conditions

Knowing what those IP ratings mean matters a lot when picking out sensors because it tells us if they'll hold up against tough environments. Take square inductive sensors for instance. When they have good IP ratings, they actually work better in places that are really rough on equipment, which naturally means they last longer too. According to industry benchmarks, sensors rated at IP67 or even IP69K handle all sorts of nasty stuff much better than their lower-rated counterparts. We're talking about things like dirt getting everywhere, water splashing around, and physical impacts from machinery parts bumping into them. These high rating sensors become essential in sectors like food processing plants or outdoor construction sites where regular sensors would just give up after a few weeks. Getting familiar with these numbers helps engineers pick the right tools for the job, saving money down the road when replacements aren't needed so often.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES