Long-Distance 40mm Detection Inductive Sensors Now Available

Understanding Long-Distance Inductive Sensor Technology

Core Principles of Inductive Proximity Sensors

Inductive sensors have become pretty much standard equipment across many industrial operations. These devices work based on electromagnetic induction principles. What makes them so useful? They can spot metal objects without actually touching them. The way they do this involves creating an oscillating magnetic field around the sensor area. When something made of metal comes near, it messes with that field, and the sensor picks up on those changes to know when something is there. This works really well in tough conditions where other sensor types would just give up. Factories dealing with dust, moisture, or extreme temperatures rely heavily on these kinds of sensors because they keep working even when things get rough. Plus, since they respond to different kinds of metals, manufacturers find them super versatile for all sorts of production lines. Safety systems benefit too, as workers don't need to worry about direct contact with potentially dangerous materials during operation.

Why 40mm Detection Range Matters in Industrial Automation

When it comes to industrial automation, having a detection range of around 40mm really makes a difference. This kind of range gives operators some breathing room when positioning components, something that matters a lot in manufacturing settings where precision counts. The extra space means sensors can spot objects reliably even if things aren't perfectly aligned, cutting down on those frustrating production stoppages we all hate. In fast moving production lines where volumes are through the roof, these longer ranges let machines work quicker without compromising safety margins. Most manufacturers know from experience that sensors capable of reaching further just plain work better over time. They cut down on unexpected breakdowns and keep the whole production line running smoothly day after day, which ultimately saves money and headaches for plant managers.

Enhanced Durability for Harsh Environments

Sensors featuring a 40mm detection range are built tough enough to handle the worst industrial settings around. These devices use heavy duty construction materials that stand up against dust buildup, water exposure, and temperature extremes from freezing cold to scorching heat. Most models have impressive IP67 or IP68 ratings which basically means they can survive being submerged in water or exposed to harsh weather conditions without failing. This kind of rugged design means plant managers don't have to replace them so frequently, saving money on parts and labor costs down the road. Factory floor experience shows that when companies invest in these tough sensors upfront, they end up spending less time dealing with equipment failures during production runs, which keeps everything running smoothly and maintains productivity levels.

Precision Targeting in Metal Detection Applications

Sensors with a 40mm detection range work really well for spotting metal objects accurately while cutting down on false alarms. They can tell the difference between different kinds of metals too, which makes them pretty useful in complicated setups. Take automotive assembly lines for instance, where even small metal fragments need to be detected before final product inspection. The precision matters a lot in manufacturing when companies need to maintain tight quality controls so finished goods pass all required specifications. Real world testing has shown factories using these sensors report better productivity numbers because they catch issues earlier in production. No wonder why food processing plants and pharmaceutical manufacturers rely heavily on this technology despite the initial investment costs.

Product Showcase: 40mm Industrial-Grade Inductive Sensors

DC 2-Wire Q40 Model: 20-25mm Sensing Distance

The DC 2-Wire Q40 model delivers solid performance across many industrial applications with its sensing range of 20 to 25 millimeters. While not the largest detection range available, this compact size works well for most factory floor needs. What really stands out is how straightforward it is to install even in cramped areas where standard sensors just won't fit. Many technicians appreciate this feature when working on conveyor systems or machinery with limited space around components. Built to last but still sensitive enough for most jobs, these sensors typically don't need replacing as often as other models on the market. That combination makes them pretty versatile for everything from assembly lines to quality control stations throughout manufacturing facilities.

Q40 Square Connector Type: M12 Interface Solutions

The Q40 square model comes equipped with a specialized connector that makes it easy to hook up to most existing equipment on the factory floor. The M12 interface has become pretty much standard across industrial automation setups these days because it creates solid, dependable connections even when faced with all sorts of harsh conditions we see in manufacturing environments. Dust, moisture, temperature fluctuations - whatever gets thrown at them, these connectors hold up well. What's great about this particular design is how straightforward it is to install, plus anyone can swap out components or upgrade parts without shutting down the whole system for hours. Maintenance teams love this since it cuts down on those frustrating production stoppages. And let's face it, when M12 connections work as intended, they just blend right into the automation workflow without causing headaches for operators trying to keep everything running smoothly day after day.

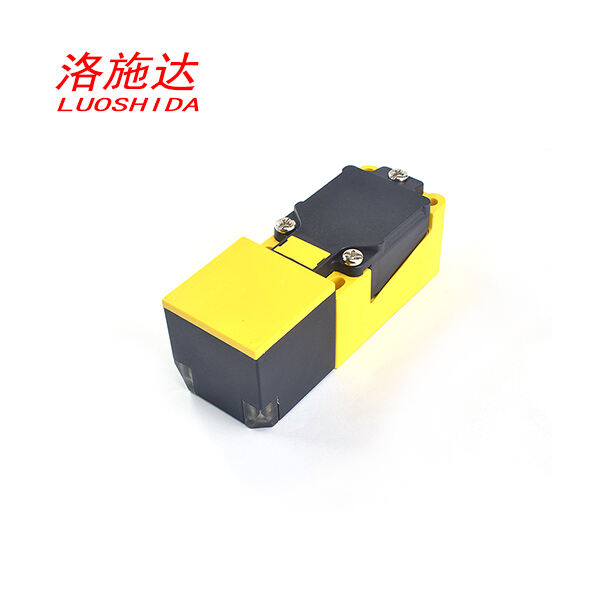

Q40S Compact Design: Space-Optimized 65mm Housing

The Q40S comes in a really compact package measuring just 65mm across, which matters a lot when working on tight spaces. Despite its small size, it doesn't cut corners on performance either, so many technicians choose it whenever installation area becomes limited. Engineers appreciate how easy it is to position these sensors wherever needed within their systems. The smaller form factor actually saves money in the long run since there's less need for extra mounting hardware or rearranging existing equipment layouts. For factories dealing with crowded production lines or maintenance teams working around legacy machinery, the Q40S offers both cost savings and reliable operation without taking up valuable floor space.

Applications Across Industries

Production Line Automation Systems

In production line automation, inductive sensors really make a difference when it comes to getting things done faster. Their main job? Spotting where products and machines are located so everything moves smoothly through the factory floor. When these sensors monitor conveyor belts and robotic arms, they keep operations running just right, cutting down on mistakes people might otherwise make. Factories that installed these sensors saw their output go up quite a bit according to several real world tests. The bottom line is better productivity across the board while making sure production lines run at peak efficiency without wasting time or resources.

Heavy Machinery Safety Monitoring

When it comes to heavy machinery operations, inductive sensors play a key role in keeping workers safe by cutting down accident risks. They work by sensing where safety covers are located on equipment, making sure machines don't start running when they shouldn't. This simple but important function stops dangerous situations from happening in workshops and factories. Safety regulations actually require companies in industries like construction and manufacturing to install these kinds of sensors. Putting them into place isn't just about following rules though. Real world experience shows that workplaces with good sensor systems tend to have fewer incidents overall, creating better conditions for everyone involved.

Advantages Over Photoelectric Sensor Alternatives

Superior Performance in Contaminated Environments

In dirty or messy environments, inductive sensors generally perform better than photoelectric ones. Photoelectric sensors work with light beams that get blocked easily when there's dust, oil splatter, or other mess around. Inductive sensors don't have this problem because they function differently altogether. They keep working reliably even when things get tough. This matters a lot in manufacturing plants, construction sites, and food processing facilities where dirt and grime are constant issues. Real world testing shows these sensors cut down on wrong readings when conditions aren't ideal. For factories needing dependable results day after day, switching to inductive makes good sense both operationally and financially.

Reduced False Triggering with Metal-Specific Detection

Inductive sensors have one major edge over photoelectric ones when it comes to detecting metal objects without getting tripped up by false signals. Photoelectric sensors tend to pick up all sorts of stuff that's not metal at all, while inductive models stick strictly to what they're meant to find. This makes them much better suited for applications where accuracy matters most, which ultimately keeps production lines running smoothly. Industry professionals regularly point out another benefit too: because these sensors are so precise, they don't need constant maintenance like other types do. Factories working with metals know this well since downtime costs money, and having reliable detection means fewer interruptions during critical manufacturing processes.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES