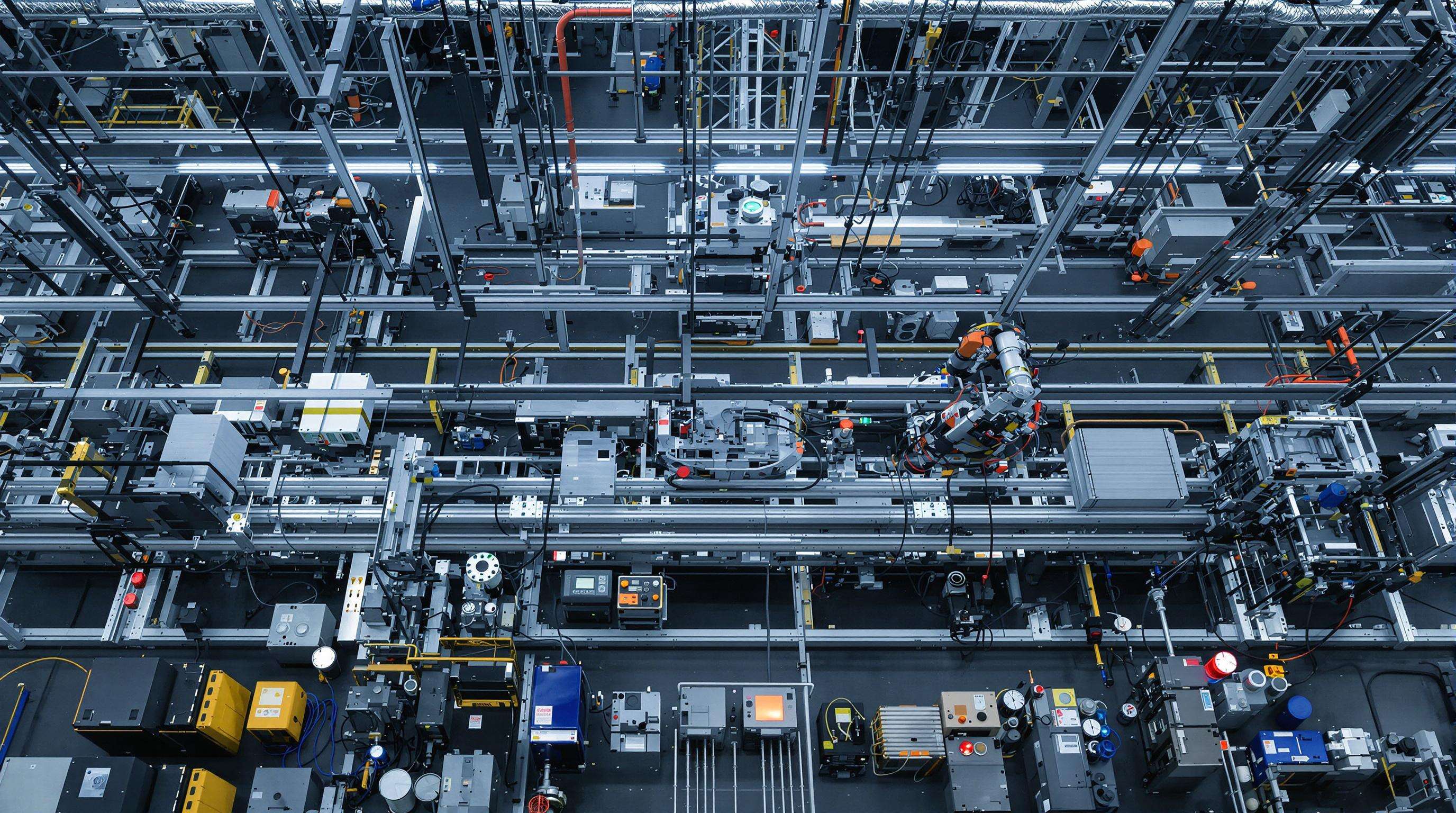

Fiber Optic Sensor Energy Savings in High-Speed Production Lines

How Fiber Optic Sensors Enable Energy Efficiency in Industrial Automation

Working Principles of Fiber Optic Sensors in High-Speed Environments

Fiber optic sensors work by sending light signals through glass or plastic fibers to pick up on things like pressure shifts, temperature fluctuations, and vibrations. When used in fast paced manufacturing environments, they have this built in protection against electromagnetic interference (EMI) that comes from all those big motors and high voltage machinery around them. Since they don't rely on electricity themselves, these sensors can actually be operated safely even in areas where explosions might happen, which means less time spent fixing systems after accidents and saves energy when production stops unexpectedly. The way light works allows for super quick response times measured in microseconds, so factories can monitor what's happening right now instead of waiting for delayed information. This matters a lot when trying to keep everything running smoothly in automated setups where timing is absolutely everything.

Energy-Saving Mechanisms: Low Power Consumption and High Signal Integrity

Fiber optic sensors actually use around 60% less power compared to traditional options out there. They typically need just between 5 and 10 volts to emit light, while older inductive or capacitive sensors require at least 24 volts. The signal quality from these optical sensors means fewer data retransmissions, which is a big deal since repeated transmissions really eat into energy budgets in factory settings. Another plus point? Fiber can carry signals across thousands of meters without needing any kind of signal boosters. This completely removes those power hungry repeaters that copper wiring systems depend on. Looking at what the industry has been finding lately, especially studies from 2025, shows that these sensors create much lower transmission losses and generate almost no heat during operation. All this makes them stand out as a real green solution for companies trying to upgrade their automated systems sustainably.

Comparison with Traditional Sensors: Efficiency, Speed, and Reliability

| Parameter | Fiber Optic Sensors | Traditional Sensors | Improvement |

|---|---|---|---|

| Power Consumption | 5-10V | 24-48V | -60% |

| Response Time | <5µs | 20-100ms | 4,000× faster |

| EMI Immunity | High | Low/Medium | No interference failures |

| Maintenance Cycles | 10+ years | 3-5 years | -50% downtime |

Source: Industrial Automation Efficiency Report (Ponemon 2023)

Fiber optic systems work differently than traditional electromechanical sensors because they don't suffer from those annoying energy losses caused by signal noise filtering or heat issues. The way these optical systems are built means they basically run themselves without needing much maintenance at all. We're talking about equipment that can keep going strong for ten years plus without breaking down or requiring constant adjustments. That really cuts down on wasted power from all those regular recalibrations that other systems need. Some real world tests in the automotive industry showed just how effective this technology is. Companies reported saving around seven hundred forty thousand dollars each year on their energy bills. Even better, these systems maintained almost perfect uptime rates of 99.98 percent while handling production volumes well over a thousand units per minute.

Quantifying Energy Savings in High-Speed Production Lines

Measuring Power Reduction in Real-World Manufacturing Settings

Fiber optic sensors offer really fine resolution when it comes to tracking temperature changes and mechanical stress, which helps factories save energy in their operations. Some research from Fysikopoulos and team back in 2024 showed pretty impressive results too. They found that putting these optical sensors on car production lines cut down energy consumption by about 20%. What makes these sensors stand out is how efficient they are. Each one only draws 0.5 watts of power, which is actually 83% less than what traditional electromechanical sensors need. Even better, they keep working reliably even at incredibly fast speeds, handling rotations over 15,000 RPM without losing signal quality. For manufacturers looking to boost performance while cutting costs, this kind of technology just makes sense.

Case Study: Energy Optimization in Automotive Production

A tier-1 supplier implemented fiber optic sensors at welding stations, achieving:

| Metric | Before Deployment | After Deployment | Improvement |

|---|---|---|---|

| Energy Consumption | 48 kW/hr | 38.4 kW/hr | 20% |

| Thermal Variance | ±12°C | ±1.8°C | 85% |

| Maintenance Intervals | 450 hours | 2,100 hours | 367% |

The system achieved payback in nine months by reducing energy waste from misalignment and overheating.

Cost-Benefit Analysis: High Initial Investment vs. Long-Term Energy Gains

Despite 30–40% higher upfront costs, fiber optic systems offer 12–15 year lifespans and $18.7k/line in annual energy savings. Manufacturers report 62% lower calibration costs and 91% fewer false alarms due to EMI immunity—essential in high-speed forging and stamping operations.

Real-Time Process Control and Line Efficiency Improvements

Ultra-Fast Feedback Loops for Precision Monitoring

Fiber optic sensors deliver microsecond-speed feedback, allowing instant adjustments to production parameters. This reduces material waste by 25% and energy deviations by 18% (Ponemon 2023). Their long-distance signal fidelity prevents cascading errors, avoiding energy-intensive rework in high-speed environments.

Enhancing Throughput in Electronics Assembly with Fiber Optic Sensing

For PCB production lines, these sensors allow contact-free inspection speeds exceeding 1000 boards per minute, with reaction times under a millisecond. Power consumption is remarkably low too, under half a watt per sensor point. That's way better than those high power vision systems, which really heat up cleanroom environments. Remember how HVAC systems eat up about 40% of total energy costs in these facilities? These sensors help cut down on that thermal burden. What's more, when connected directly to PLC systems, they keep production moving at full speed even while running quality inspections, so there's no need to slow things down for checks.

Integration with Smart Manufacturing and IIoT for Sustainable Operations

Seamless Connectivity with Industrial Internet of Things Platforms

Fiber optic sensors support IIoT ecosystems with sub-millisecond latency and 60% lower energy use than copper systems. Their EMI resistance ensures reliable communication in heavy industrial settings, enabling synchronized automation. Germany’s Industrie 4.0 initiative reports 25% productivity gains in factories using fiber optic-IIoT integration, driven by efficient machine-to-cloud data flow.

Data-Driven Predictive Maintenance to Reduce Downtime and Energy Waste

By feeding real-time vibration and temperature data into AI models, fiber optic sensors reduce unplanned downtime by 40% in automotive lines. This prevents costly, energy-intensive equipment overhauls. In semiconductor plants, they cut cleanroom energy use by 18% through optimized HVAC during calibration cycles.

Lifecycle and Sustainability Impact of Fiber Optic Sensor Deployments

With a 10-year lifespan—double that of photoelectric sensors—fiber optics reduce e-waste by 53% (Ponemon 2023). Their silica construction requires 68% less production energy than copper-based systems, supporting circular economy goals. When paired with digital twins, they help facilities meet ISO 50001 standards through auditable energy performance records.

Frequently Asked Questions

What are fiber optic sensors used for in industrial settings?

Fiber optic sensors are used to detect pressure shifts, temperature changes, and vibrations, enabling efficient monitoring of production lines with high immunity to electromagnetic interference.

How do fiber optic sensors save energy compared to traditional sensors?

Fiber optic sensors consume about 60% less power, only requiring 5 to 10 volts to operate, as opposed to up to 48 volts for traditional sensors, and they eliminate the need for power-hungry repeaters.

Are fiber optic sensors suitable for high-speed manufacturing environments?

Yes, fiber optic sensors have ultra-fast response times, measured in microseconds, making them ideal for real-time monitoring in automated and high-speed production settings.

What initial investment is required for fiber optic systems?

Fiber optic systems may have a 30-40% higher upfront cost compared to traditional sensors, but they offer long-term energy savings and reduced maintenance costs, resulting in quick payback.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES