Inductive Proximity Sensor Miniaturization Trends for Compact Equipment

Enabling Space-Efficient Automation in Compact Equipment

The tiny size of modern inductive proximity sensors solves some serious space issues across various industries including medical tech, robotics, and high-precision manufacturing. These little guys, sometimes smaller than 8mm across, can actually squeeze into spots that were totally out of reach before. Think about them nestled inside those complicated robotic arm mechanisms, hidden behind the control boards of handheld diagnostic tools, or even running alongside miniature assembly line conveyors. A recent report from Motion Control Engineering (2024) found something interesting too: around seven out of ten automation engineers are making sensor size their main concern when they need to upgrade old equipment for tight spaces.

Core Functionality in High-Density Mechanical Environments

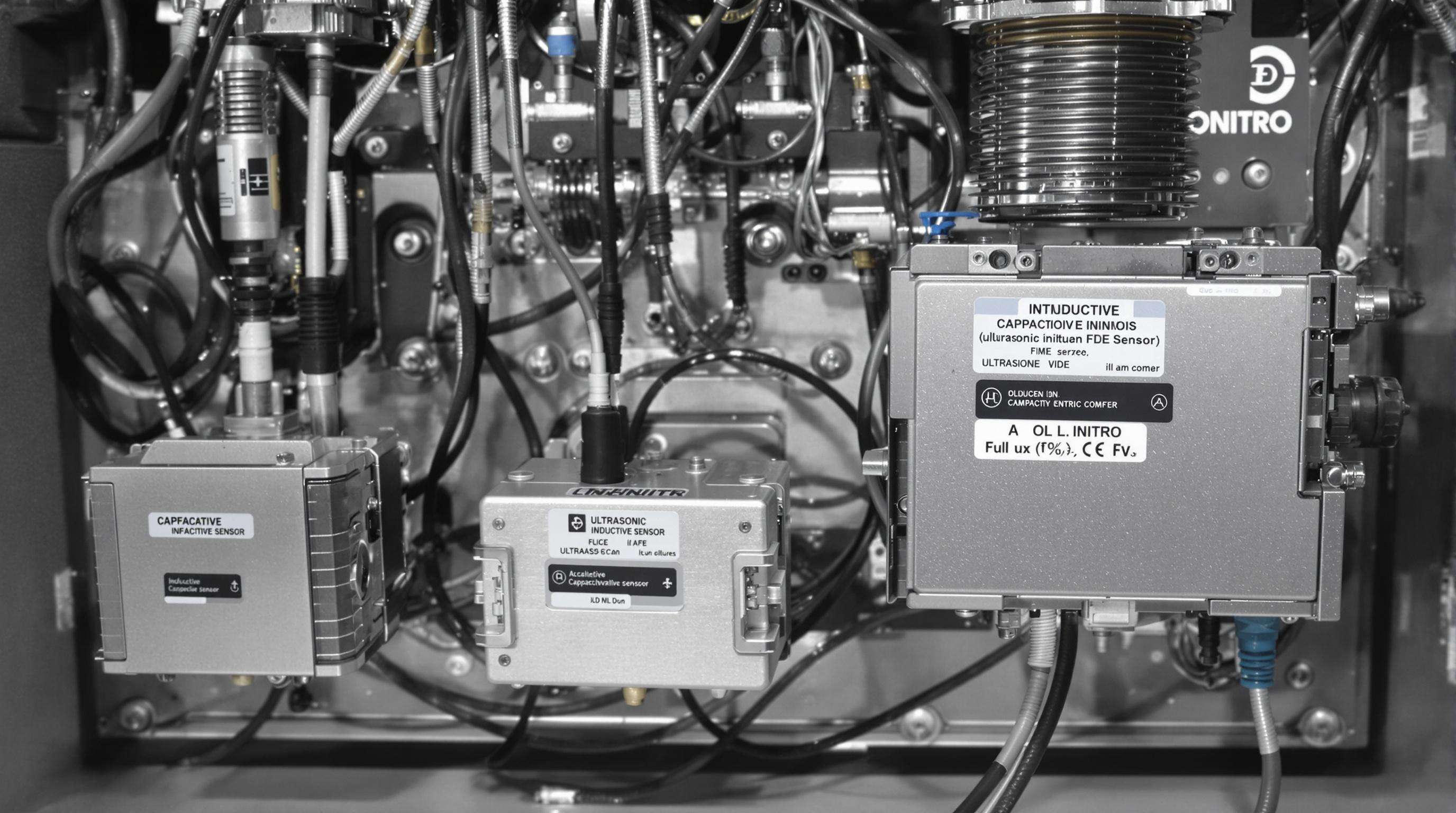

Inductive sensors deliver reliable, non-contact detection in crowded mechanical setups where vibration, metal debris, and temperature swings threaten performance. Their solid-state design ensures longevity in demanding applications such as:

- Toolchanger mechanisms in CNC mills

- 3D printer extruder positioning systems

- Safety interlocks in high-vibration packaging machinery

Unlike optical sensors, which are prone to interference from dust or fluids, inductive sensors maintain micron-level accuracy even when mounted near motors or hydraulic components.

Advantages Over Alternative Sensing Technologies in Constrained Spaces

In space-critical applications, inductive sensors outperform capacitive and ultrasonic alternatives due to their superior environmental resilience and compactness:

| Factor | Inductive Advantage |

|---|---|

| False Trigger Rate | 83% lower than capacitive sensors near non-metallic materials |

| Power Consumption | 45% less than comparable ultrasonic models (Ponemon 2023) |

| Temperature Tolerance | Operates from -40°C to 100°C without recalibration |

This blend of efficiency and durability makes them essential for high-reliability systems where size and stability directly impact success.

Key Drivers Accelerating Miniaturization of Inductive Proximity Sensors

Rising Demand for Compact Equipment in Medical, Robotics, and Consumer Electronics

The push for smaller automation stems from medical imaging systems requiring 50% smaller sensors than 2020 models, collaborative robots needing sub-8mm detection, and wearables demanding <5g modules. Over 75% of new robotics prototypes now use M5-form factor sensors to function in spaces 40% tighter than 2015-era designs.

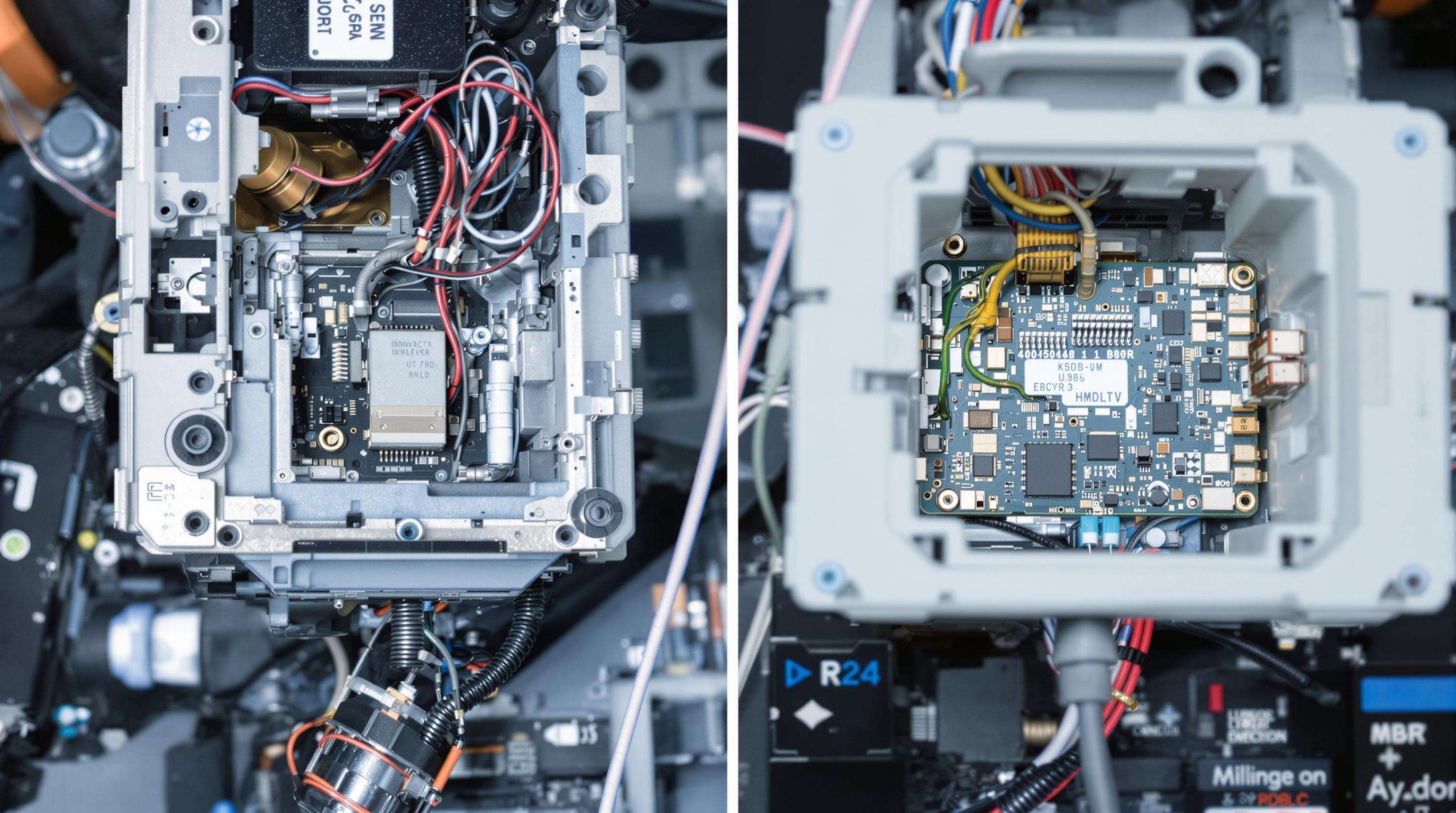

Micro-Coil and ASIC Integration Breakthroughs Reducing Sensor Footprint

ASIC integration has condensed signal conditioning and thermal compensation into 3mm² chips, cutting total sensor size by 60%. Advanced micro-coil etching enables 0.1mm precision windings, delivering 12mm sensing ranges in housings smaller than a button cell battery.

Material Innovations Enabling Durability at Smaller Scales

Nano-crystalline ferrite cores withstand 150°C while operating at 1MHz, maintaining accuracy in vibrating machinery. High-temperature polymers like PEEK-Ultem replace metal housings, reducing weight by 70% while meeting IP69K standards for dust and moisture resistance.

Overcoming Thermal and Electromagnetic Challenges in Miniaturized Designs

The symmetric arrangement of coils along with guard ring configurations can cut down on electromagnetic interference by around 20 decibels, which is really important for devices implanted inside the body. When it comes to temperature stability, phase locked loops have managed to keep thermal drift below 1% across temperatures ranging from minus 40 degrees Celsius all the way up to 125 degrees Celsius. That represents roughly a third better performance compared to what we saw in previous compact designs. What makes these improvements so valuable is that they let inductive sensors work properly in situations where traditional optical methods simply won't function. Looking ahead, there's growing expectation that integrating edge artificial intelligence will lead to even smaller sensor packages, potentially reducing sizes by about 40 percent within the next few years according to industry forecasts.

Size Reduction Trends: Evolution and Impact on Compact Equipment Integration

Historical evolution of inductive sensor dimensions since 2015

Since 2015, inductive sensors have rapidly shrunk due to growing space constraints in modern machinery. After incremental reductions in M12 housings, breakthroughs in microelectronics post-2018 enabled dramatic downsizing. Chip-scale integration allowed sensors to shrink from over 20mm to under 8mm in diameter while preserving sensing performance.

Data insight: 40% average size reduction in M8 and M5 sensor formats

M8 and M5 formats have achieved a 40% average volume reduction since 2015âthe most among industrial sensors. This enables 68% higher installation density in control panels and robotic joints. Importantly, key performance metrics like ±15% sensing range and switching frequency remain stable, overcoming traditional trade-offs through optimized coil geometry.

Role of PCB-based coil winding in advancing miniaturization

PCB fabrication transformed coil manufacturing by enabling photolithographic precision unattainable with manual winding. Multi-layer circuits now integrate coils under 3mm in diameter with tolerances below 0.05mm. This semiconductor-grade process supports 15% thinner housings and improves EMI resistance via controlled impedance pathsâessential for rugged compact equipment.

Engineering Principles Behind High-Performance Miniature Inductive Sensors

Optimizing Operating Frequency in Sub-10mm Sensor Housings

Sensors under 10mm require precise frequency tuning to maintain detection accuracy. Engineers use frequency-shift keying to offset reduced coil diameters and minimize cross-talk in dense configurations. Thin-film fabrication allows modern <4mm sensors to operate at 500 kHzâ2 MHz, enabling reliable detection of sub-millimeter metallic targets.

Maintaining Signal-to-Noise Ratio Despite Reduced Coil Size

A 2023 Sensor Miniaturization Report noted a 34% SNR improvement in miniature sensors over 2019 models, driven by:

- Multilayer PCB coils with 0.05mm trace spacing

- Differential signal processing architectures

- Active noise cancellation algorithms

These innovations support 0.5mm ferrous metal detection in sensors occupying just 8% of the volume of 2015-era models.

Power Efficiency and EMI Resistance for Reliable Compact Equipment Integration

Modern miniature inductive sensors consume 72% less power than standard versions and offer 12kV ESD protection and 100 V/m EMI immunity. Energy recovery circuits and shielded encapsulation enable safe use in medical implants and high-density robotics, where space prevents traditional shielding.

Trade-offs Between Sensor Size and Sensing Range: Performance Considerations

The industry-standard 4:1 size-to-range ratio poses challenges for sub-6mm designs. While an M8 sensor typically detects targets at 2mm, its M5 counterpart achieves only 1.2mm rangeâa 40% reduction for 60% size savings. Advanced phase-compensation algorithms now recover 22% of lost range in 3mm sensors without compromising packaging constraints.

Real-World Applications and Future Trends in Compact Equipment

Case study: Sub-millimeter positioning in surgical robotics

The tiny inductive sensors used in neurosurgical robots can actually measure with about 0.05mm accuracy, which helps surgeons navigate those really delicate areas of the brain without causing damage. What makes them special is their ability to work properly even when there are strong MRI magnetic fields around or when electrosurgical instruments are being used something that tends to mess up regular optical sensors completely. Some tests done last year at one of the top medical research facilities showed pretty impressive results too these new sensor systems cut down on the time needed for spinal implant procedures by nearly 18 percent according to their findings.

Case study: Embedded sensing in automated insulin delivery systems

Insulin pumps use 3.5mm inductive sensors to verify dose mechanism alignment, achieving 99.97% delivery accuracy. Their non-contact design prevents wear particles, meeting ISO 13485 standards for implantable devices. Clinical data shows a 42% reduction in mechanical failure rates compared to Hall-effect sensors in continuous glucose monitors (Diabetes Technology Society 2022).

Case study: Collaborative robot joints with integrated miniature sensors

Cobots embed <10mm inductive sensors directly in harmonic drive gear teeth to monitor joint angle (±0.1°) and detect human proximity within 5mm. This dual function reduces wiring complexity by 35% in sixth-axis joints while maintaining sub-1ms response times for collision avoidanceâessential in tight assembly environments.

Emerging trends: IoT and edge processing integration in miniature sensors

New M8-sized sensors integrate ARM Cortex-M0+ processors that perform onboard hysteresis compensation, reducing PLC workload by 22% in compact CNC machines (Embedded Systems Report 2023). This enables real-time tool wear monitoring in dental milling units without expanding control cabinet sizeâadvancing Industry 4.0 readiness in space-limited systems.

Future outlook: Wafer-level packaging and nanomaterials enabling 60% further size reduction by 2030

Researchers have demonstrated graphene-oxide sensor coils achieving 8mm detection ranges in 60% smaller volumes than copper-based designs. Combined with MEMS wafer-level packaging, this could yield sub-3mm sensors for micro-drone landing systems by 2028, with mass production feasible by 2030 (Nanoelectronics Roadmap 2023).

FAQ

What are inductive sensors, and how do they work?

Inductive sensors are devices used for non-contact detection of metallic objects. They work by generating an electromagnetic field, and when a metal object is near, the field is disturbed, resulting in a change in the sensor's signal.

How do inductive sensors differ from optical sensors?

Inductive sensors do not rely on light or visuals for detection. They are less prone to interference from dust, dirt, or fluids compared to optical sensors.

Why is miniaturization important in sensor technology?

Miniaturization allows sensors to fit into compact and tight spaces, enhancing the performance and versatility of modern equipment like robotics and medical devices.

What are key industries using miniaturized inductive sensors?

Industries like medical technology, robotics, and consumer electronics are increasingly using miniaturized inductive sensors for space-efficient automation and high-reliability systems.

What future trends are anticipated in sensor miniaturization?

Advancements such as wafer-level packaging and nanomaterials are expected to further reduce sensor sizes, possibly by up to 60% by 2030, enhancing compact equipment integration and functionality.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES