Laser Sensor Precision Without Extra Cooling: How Green Design Cuts Waste

The Impact of Laser Sensor Precision on Sustainable Manufacturing

How Laser Sensor Precision Enables Waste Reduction in Precision Engineering

When laser sensors are used for cutting and engraving tasks, they significantly cut down on wasted materials because they can hit targets with incredible precision at the micron level. This means thinner kerf widths and fewer mistakes during production runs. According to recent industry data from 2024, manufacturers report saving around 30% on raw materials when switching from old school techniques to these advanced systems. With so few defects coming out of the process, there's just not as much need for fixing things later on, which saves both time and energy normally spent on corrections. Plus, the ability to tweak alignments while working keeps everything running smoothly in factories making aircraft parts, car components, and even tiny chips for electronics, all while keeping scrap rates low throughout these demanding industries.

Integrating Ultrashort-Pulse (USP) Lasers for Energy-Efficient Micromachining

Ultrashort Pulse (USP) lasers work by firing incredibly short bursts at material surfaces, basically vaporizing what needs to go without creating heat buildup. This means no need for those bulky liquid cooling systems which usually eat up around 40% of the total energy in traditional setups. According to recent studies looking at green manufacturing practices across different industries, switching to USP tech cuts down on power usage somewhere between 25% and 35% per machine while still keeping that amazing level of detail below one micrometer. The absence of coolant fluids not only saves money but prevents all sorts of problems related to hazardous waste disposal and potential water pollution issues. For manufacturers making parts that require tight tolerances, this represents a real step forward in sustainable production methods without sacrificing quality standards.

Case Study: High-Precision Laser Manufacturing in Medical Device Production

One maker of heart devices switched to using laser micromachining for their stents and surgical instruments, which cut down on resources needed. The laser etching process slashed titanium waste by around 32% because they could fit parts together better in the manufacturing space. They also started using USP surface treatments instead of chemical polishing methods, cutting out about 15 tons of solvents every year from their waste stream. When they took the old coolant systems offline, energy consumption went down by nearly 28%. And with almost no defects showing up in production runs, they managed to get close to 98% material usage when making batches of 50,000 units. What this shows is that these sensor controlled laser systems aren't just improving medical product quality but are actually helping manufacturers meet those tough sustainability targets at the same time.

Eliminating Cooling Overhead: Green Design Advancements in Laser Systems

Environmental Costs of Traditional Laser Cooling Systems

Traditional water-based cooling systems account for 15–30% of total operational energy in industrial laser applications. They cost manufacturers over $740,000 annually in maintenance and infrastructure (Ponemon Institute 2023), while posing environmental risks through water contamination and refrigerant emissions—averaging 2.4 tons/year per production line, equivalent to the annual emissions of 52 passenger vehicles.

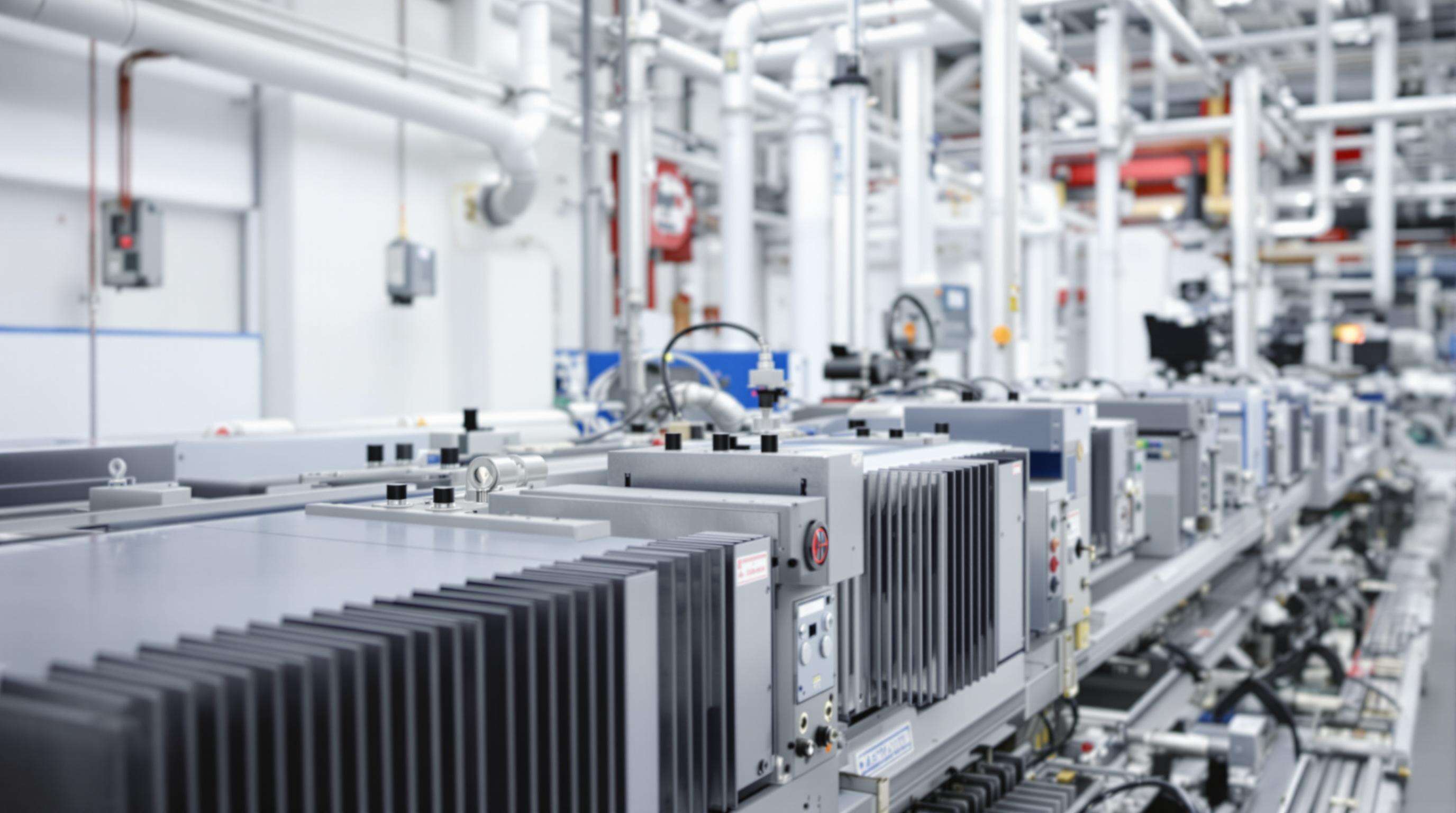

Innovative Passive Cooling Designs That Preserve Laser Sensor Precision

The latest rack mount diode lasers now incorporate 300 micrometer fiber delivery along with improved thermal management techniques that allow them to run without needing external chillers. The passive cooling approach keeps position stability below 0.1 micrometers which is really important when doing things like etching medical devices where even tiny movements matter a lot. And they do all this while consuming way less power than older water cooled models. Some real world testing has demonstrated around a two thirds drop in energy usage compared to those traditional systems. Plus these units can handle continuous operation for days on end at full 500 watt capacity without breaking a sweat.

Evaluating Performance Trade-offs in Cooling-Free Laser Operations

According to recent industry data from LIA (2023), air cooled systems actually perform just as well as their water cooled counterparts when it comes to cutting precision across most sheet metal work, around 93% of cases to be exact. These systems also take up about 19% less space on the factory floor which makes them easier to move around and reconfigure when production needs change. The downside? They need much stricter temperature control in the environment where they operate, typically needing to stay within a narrow range of plus or minus 1.5 degrees Celsius compared to the wider tolerance of plus or minus 5 for water cooled versions. Manufacturers who have switched over are seeing some pretty impressive results too. One plant manager mentioned they experienced roughly 40% fewer stoppages because these air cooled machines don't suffer from those annoying issues that plague water systems all the time like pumps failing or minerals clogging things up.

Lifecycle and Industrial Benefits of Eco-Friendly Laser Precision Systems

Reducing Material and Chemical Waste Through Laser Sensor Precision

The precision offered by laser sensors really helps tackle sustainability issues because it makes better use of materials while cutting down on chemicals needed for production. When manufacturers achieve accuracy at the micron level, they end up wasting far less material than traditional approaches do according to industry data from last year showing reductions as high as 34%. Take battery manufacturing for instance where these fast acting lasers have completely replaced chemical etching processes that used harmful solvents throughout production lines. What's even better is how this kind of precise work minimizes extra steps after initial processing such as grinding or polishing operations which typically consume additional energy resources somewhere between 20% to 30% more than what would otherwise be necessary.

Lifecycle Analysis: Sustainability Gains in Green Laser System Deployment

Modern eco-friendly laser systems deliver measurable sustainability improvements over their operational lifespan:

| Metric | Traditional Systems | Green Laser Systems | Improvement |

|---|---|---|---|

| Energy Consumption | 8.2 kW/h | 5.1 kW/h | 38% Reduction |

| CO2 Emissions | 12.4 t/yr | 7.8 t/yr | 37% Reduction |

| Component Lifespan | 45,000 hours | 100,000+ hours | 122% Increase |

Passive cooling and modular designs extend service intervals, reducing replacement part waste by 60% over a 10-year lifecycle.

Scaling Green Laser Technology in B2B Industrial Manufacturing

Four factors are accelerating adoption in heavy industry:

- Energy-to-Precision Ratio: New fiber lasers deliver 50W performance with 30% lower energy consumption than legacy systems

- Retrofit Compatibility: 72% of CNC machines can integrate laser modules without full system replacements

- Regulatory Alignment: Supports compliance with ISO 14001 and EPA standards for chemical-free, low-waste processing

- Total Cost: Offers an 18-month ROI through energy savings and reduced hazardous waste disposal

This scalability establishes laser sensor precision as a foundational technology for achieving Scope 3 emissions reductions in aerospace, automotive, and medical device manufacturing.

Frequently Asked Questions

What are the advantages of using laser sensors in manufacturing?

Laser sensors enable high precision in manufacturing, reducing material waste, increasing energy efficiency, and minimizing defects, leading to cost savings and improved sustainability.

How do ultrashort-pulse lasers contribute to sustainability?

Ultrashort-pulse lasers reduce energy consumption by eliminating the need for liquid cooling systems and cut down hazardous waste by avoiding pollutants like solvents.

Why is passive cooling beneficial for laser systems?

Passive cooling eliminates the environmental and operational drawbacks of traditional water-based cooling systems, reducing energy costs and environmental impact while maintaining precision.

What sustainability gains can green laser systems offer?

Green laser systems offer 38% reduction in energy consumption, 37% lower CO2 emissions, and over double the component lifespan compared to traditional systems.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES