How Moisture Sensors Can Shield Your Products from Humidity Risks

The Hidden Dangers of Humidity in Product Storage

Moisture levels in storage areas create real problems for products across many different sectors. When humidity gets out of control, even small amounts of dampness can cause serious issues down the line. For businesses, knowing what goes wrong with improper humidity management helps keep inventory intact, preserves product quality standards, and ultimately keeps customers happy with their purchases. Looking at actual cases where moisture damaged goods shows just how widespread these problems are. Certain industries face greater risk than others when it comes to humidity fluctuations, making proper climate control absolutely essential for operations.

Common Types of Moisture-Related Product Damage

When moisture gets into products, it causes all sorts of problems like mold growth, rust, and corrosion. Mold and mildew are real troublemakers that ruin product quality and put workers at serious health risk. We've seen this happen time and again in warehouses where damp conditions lead to respiratory issues among staff. The Centers for Disease Control has actually published reports showing how dangerous mold exposure can be. Rust isn't just about rusty nails either. It eats away at machines too, which means costly fixes and production stoppages nobody wants. And let's not forget about condensation. This invisible enemy spoils delicate stuff, especially important when dealing with food storage or medicines. The World Health Organization points out that improper humidity control in pharmacies leads to medicine degradation. That's why keeping things dry matters so much across industries.

Industries Most Vulnerable to Humidity Risks

Certain sectors just cannot tolerate fluctuations in humidity because of what they produce and government rules they must follow. Take food storage facilities for example, where even slight changes in air moisture can lead to mold growth on perishables like dairy products or fresh fruits. The pharmaceutical industry faces similar issues too. Medications need stable environments during manufacturing and storage periods otherwise their effectiveness drops off completely. A study from IMS Health actually showed how keeping humidity within narrow ranges keeps drugs safe for patients. Electronics manufacturers deal with different problems altogether when moisture gets involved. Circuit boards start corroding over time if exposed to damp conditions, which eventually leads to component failure down the road. And let's not forget about textile mills either. Fabric quality deteriorates rapidly under high humidity conditions according to findings published in Textile Research Journal, while paper producers struggle with warping sheets and ink smearing across pages. All these businesses really need constant monitoring systems in place to protect against unexpected damage caused by improper moisture levels.

How Inductive Moisture Sensors Detect Environmental Threats

Working Principles of Inductive Proximity Sensors

Inductive proximity sensors work really well for spotting moisture because they generate an electromagnetic field around them. What makes these devices so good at their job is that they give consistent readings which help keep workplaces safer overall. How they actually function involves picking up on changes in capacitance whenever there's moisture nearby, which then tells whoever needs to know about possible problems before things get bad. When placed properly throughout different settings, these sensors catch those first signs of dampness forming, something that regular inspection might miss completely. Some studies show that putting these kinds of sensors to work cuts down product damage by roughly 40 percent in sectors where water damage is a big concern. For manufacturers dealing with sensitive materials or equipment vulnerable to humidity, adding inductive proximity sensors means being able to spot trouble spots ahead of time rather than waiting for expensive repairs later on.

Advantages Over Traditional Humidity Monitoring

Inductive sensors beat out old school humidity monitoring techniques because they respond much faster, which really boosts how well operations run. The fact that they give real time readings matters a lot when trying to stop water damage in places like pharmaceutical warehouses or food storage facilities where even slight changes matter. These modern sensors last longer too and aren't hard to install compared to the clunky systems from years ago, so they save money overall. Plus, they need almost no upkeep and can recalibrate themselves automatically, making sure they keep working properly for years. For companies looking to protect their goods from dampness problems without breaking the bank, switching to inductive sensors makes sense both technologically and financially. Warehouses that made this switch report fewer spoiled products and smoother day to day management since implementing the new technology.

Top Industrial Moisture Sensors for Humidity Protection

Q5 Square Inductive Sensor: Rugged Space-Saving Design

The Q5 Square Inductive Sensor stands up well against tough conditions, which makes it great for factories dealing with lots of moisture in the air. Built tough from the ground up, this sensor keeps working properly even when things get really rough around the shop floor. What sets it apart though is its small square footprint that actually fits nicely into tight spaces where other sensors might struggle to find room. Many plant managers appreciate how much easier it becomes to install these units compared to bulkier alternatives, especially when retrofitting older equipment. Food processing plants and chemical manufacturing facilities have found particular value in this design since they often face persistent humidity issues that standard sensors just cant handle over time.

Q5 Square Sensor with Brass Housing

The Q5 Square Sensor comes with a brass housing that really boosts its ability to resist corrosion, which means it lasts much longer than standard models. Brass works especially well where there's lots of moisture in the air or when sensors are exposed to harsh chemicals, since it stops them from breaking down over time. Another plus is how this brass construction helps get rid of heat better, so the sensor keeps running at peak performance even after months of continuous operation. For facilities dealing with tough environments like chemical processing plants or coastal areas, this brass housing makes all the difference in getting accurate readings day after day without worrying about equipment failure.

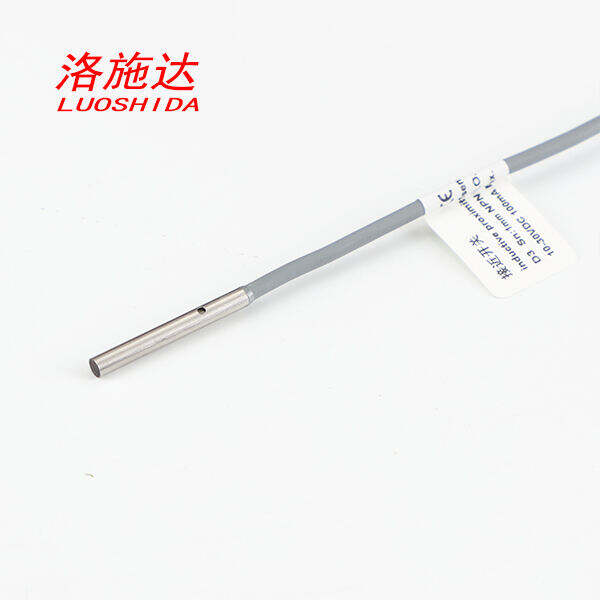

D3 Mini Inductive Sensor: Compact Solution for Tight Spaces

Designed specifically for those tricky tight spots, the D3 Mini Inductive Sensor works great when there's simply no room for bigger alternatives. The tiny size means it fits right into all sorts of small machines and equipment where space is at a premium, yet still delivers solid performance. What really stands out is how sensitive this little guy actually is. It picks up on moisture changes accurately even when installed in cramped conditions that would challenge other sensors. Built with robust materials and featuring cutting edge inductive tech, manufacturers across various industries have found the D3 Mini particularly useful in automated systems, robotic setups, and production line monitoring applications where reliable moisture detection matters most.

Implementing Sensor Technology in Your Protection Strategy

Installation Best Practices for Laser-Level Accuracy

Getting the alignment right during installation really matters when it comes to sensor performance, and that's where laser level sensors come into play. These devices give much better measurement accuracy than standard tools, so there are fewer errors in readings and the whole moisture detection system works more reliably. Most manufacturers recommend checking and adjusting these sensors regularly based on their specs. Over time, even small changes can affect how well they work, so keeping them properly calibrated makes all the difference. We've seen cases where neglecting this simple maintenance step led to major problems down the line, costing both time and money to fix.

Maintenance Tips for Long-Term Sensor Reliability

Regular maintenance and cleaning really matters when it comes to getting the most out of moisture sensors over time. What this means in practice is using proper cleaning solutions that won't harm sensitive parts while keeping everything working as intended. Don't ignore those warning signals either. When a sensor starts flagging something wrong, fixing it right away makes all the difference. Let small problems linger and they tend to turn into big headaches later on. A quick response now saves headaches and money down the road, ensuring these devices keep performing reliably for years instead of just months.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES